Steel Balls are used for polishing and burnishing and is recommended for aggressive processes. Its substantial weight (heavier than carbon steel) exerts added pressure and increased resistance to effectively reduce finishing time. Steel Balls impart compressive stress, improves pre-plate finish and reduces porosity on plated parts. It also eliminates or reduces the need for compounds and rust inhibitors and eliminates iron contamination.

Steel Balls allow for faster finishing times, eliminates the need for expensive, consumable compound solutions and rust inhibitors, and reduces the storage, maintenance and handling costs of carbon steel media. Rust inhibitors are usually unnecessary and maintenance procedures for overnight and longer-term shutdowns are considerably simplified. Steel Balls more effectively resist damage should the compound delivery system fail and the vibratory process continue. It also eliminates iron impregnation of components from the chemical interactions that take place during some finishing processes.

Features

Moderate hardness, high toughness, impact resistance, can be continuously reused several times, long life and good rebound, strong adhesion, clean sand with low speed and consumption, not broken, clean piece brightness, technological effect is good, after dealing with this product cleanliness of the metal surface up to international standards.

Surface roughness up to 25-100um, thus increasing the contact surface of the metal surface to improve adhesion of the coated surface on the refinement of metal surface hardening of metal structures, with very significant economic benefits, is currently the most advanced at home and abroad, the ideal clean-up spray polishing, rust and enhanced quality materials.

Applications:

Grinding of solids and fluids, Liquids dispersion, Fine particle size reduction, Homogenization of fillers and raw materials, Attrition and pulverizing applications in ball, vibro, dyno, pearl, bead, pebble, attritor and small-media mills, vertical or horizontal.

Industries:

- Paints, varnish, lacquers, glazes, pigments, enamels, polymers, colours, elastomers, dyestuff.

- Offset printing inks, toners.

- Metal powders and oxides, flake powders, brass, copper, iron, ferrites, aluminum, zinc, minerals, ores.

- Chemicals, talc, drugs, pharmaceuticals, cosmetics.

- Paper and electronic coatings, magnetic tape coatings, carbon black and carbon paper coatings.

- Agricultural flowables, confectionery, food products.

- Ceramics.

- Gas, oil well drilling.

- Roasted cocoa nibs, chocolate liquor.

Chemical Composition

| Carbon(C) | 0.85-1.10 |

| Silicon(Si) | 0.40-1.50 |

| Manganese(Mn) | 0.80-1.20 |

| Chromium(Cr) | 0.90-1.20 |

| Mo | 0.15-0.25 |

Density: 7.8 g/cm3

Hardness: 550 HV

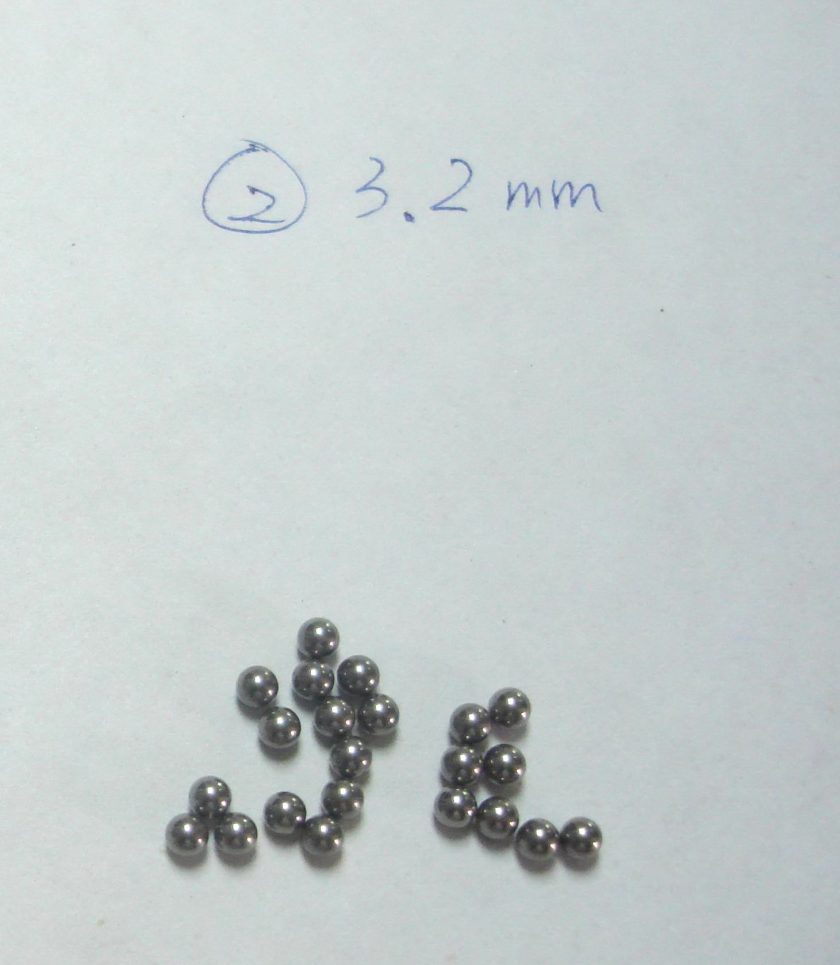

Grain class available:

Sizes from 1mm to 12.7mm and 3/64″ to 1/2″ diameters.

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.