Technically supported by Zhejiang Shengde Polishing Technology, we provide mass polishing equipment as below:

- Straight Wall Vibratory Machine

Application is for grinding process and polishing process for large quantity of parts. It will result in no damage to parts and change the size and shape after the process. Can be customized for height, motor power, control box, sound cover.

2. Vibratory Machine with Separator

Vibratory machine for grinding and polishing process, with high performance motor, strong vibration and low maintenance. Using a separator gives advantages of saving time and cost.

3. Vibratory Machine with Separator by manual Blade

Vibratory machine for grinding and polishing process, with high performance motor, strong vibration and low maintenance. Using a separator gives advantages of saving time and cost.

4. Curved Wall Vibratory Machine

Curved wall bowl has stronger tumbling, and more extrusion pressure than the straight wall vibratory machine (1.2 - 1.5 times higher).

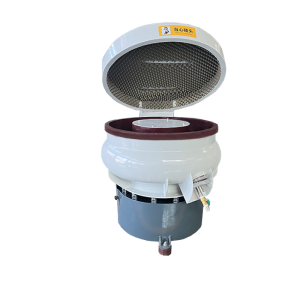

5. Centrifugal Disc Finishing Machine

There are three types of machines:

- LDH Series

Centrifugal Disc Finishing Machine which has the frequency adjustment and also can adjust the speed rotation. It has manual turnover of download, simple structure and easy operation. - LDL Series

Centrifugal Disc Finishing Machine which has the frequency adjustment, and also can adjust the speed rotation. The equipment is discharged by manual. The advantages are small area, simple operation and high price-performance ratio. - LDS Series

Centrifugal Disc Finishing Machine which has frequency adjustment, electric turnover download and vibrating screen. This machine is a semiautomatic polishing equipment. The size holes of seperator can be made according to customer request. The equipment has low noise, no material spatter, good working environment and high polishing efficiency.

6. High Precision Centrifugal Disc Finishing Machine

The machine is a high-speed mobile polishing machine, which can be used for dry grinding and wet grinding. We can choose automatic and manual discharge. The barrel use high wear- resistant ceramics and tungsten alloy ring structure, and the barrel ring has a small gap, so it is suitable for grinding thin workparts.

7. Centrifugal Machine

The machine is driven by timing belts, so it creates low noise, long service life and smooth operation. The barrel is lined with PU, which can effectively prolong the working life.

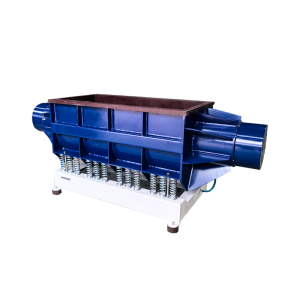

8. Extended Straight Wall Vibratory Machine

Extended Straight Wall Vibratory Machines are used for long spare parts, such as major axis, strip shape pressing. The tumbling effect of media and work parts is more effective. The vessel interior can be separated into several units, preventing the work parts from colliding with each other.

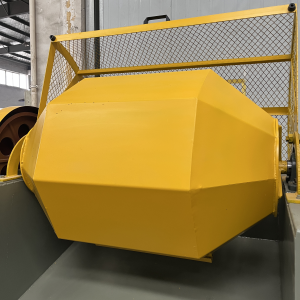

9. Rotary Barrel Polisher

Rotary Barrel Polisher uses an inverter to adjust speed rotation. With safety cover & discharge hopper will improve work efficiency. The barrel is lined with PU, which resists acid, alkali corrosion, and increases work life. The machine is driven by a V belt, no noise.

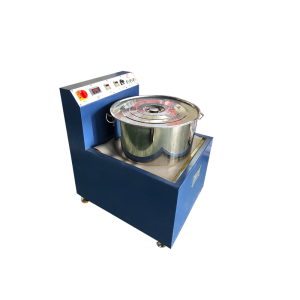

10. Centrifugal Dryer

Centrifugal Dryer uses centrifugal drying and hot air drying to achieve the drying effect. The drum rotation can be stopped by the penal brake device. The inner tank with stainless steel material can be taken out for loading and unloading the work parts.

12. Vibratory Dryer

Vibratory Dryer adopts the drying mode of vibration method and direct heating pipe, which has the advantages of high thermal efficiency and fast drying. It can quickly eliminate the water stains on the surface of work parts after grinding, and can combine with the previous grinding machine to form an automatic polishing line.

13. Magnetic Force Finishing Machine

For further information, you can contact our Sales Engineer, or you can contact us directly or here.