Brown Aluminium oxide has high density and sharp, angular structure make it one of the fastest cutting abrasives available. It has long-lasting blasting abrasive that can be recycled many times. It is the most widely used abrasive in blast finishing and surface preparation because of its cost, longevity and hardness, harder than other commonly used –blasting materials.

It is an extremely durable and tough alumina with low metallic iron content and is ideal for applications where fast cutting and consistent quality is required.

Application :

Grinding, Polishing, Blasting, Refractory, Cleaning, Removing Corrosion, Roughening, Etching and Decorating

White Aluminium Oxide has the characteristics of high hardness (second hardest mineral after diamond), sharpness, tenacity, stable chemical property, heat resisting and corrosion resisting. This sharp angular abrasive is fast cutting and is silica free.

It is the most widely used abrasive in blast finishing and surface preparation because of its cost, longevity and hardness. Harder than other commonly used blasting materials, white aluminium oxide grains penetrate and cut even the hardest metals and sintered carbide.

Applications:

White aluminium oxide blasting media has a wide variety of applications, including cleaning engine heads, valves, pistons and turbine blades in the aircraft and automotive industries. White aluminum oxide is also an excellent choice for preparing a hard surface for painting.

High quality applications where no contamination can be tolerated, makes it ideal for blasting of materials such as stainless steel, titanium, lead crystal glassware and other materials where surface cleanliness is imperative.

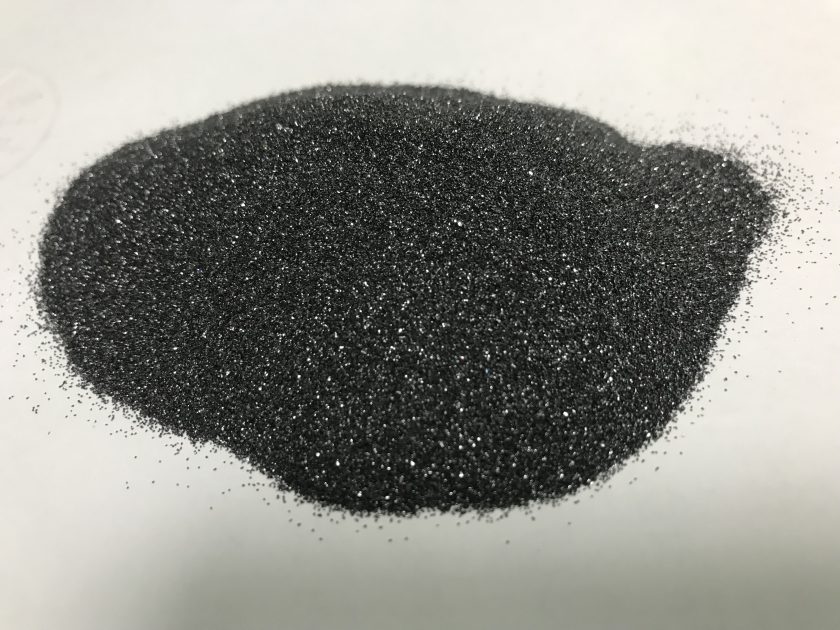

Silicon Carbide Blasting Media is an abrasive materials manufactured by combining silica sand with carbon in an electric resistance furnace. It is chemically inert and is also harder than any of the alumina products.

It is ideal for applications where rapid or aggressive surface treatment is required.

Applications:

Cleaning and roughening of the hardest surfaces, including glass and stone.

Garnet particles are sub-angular in shape resulting in extremely fast cutting rates and low abrasive consumption. The high specific gravity of the abrasive grains, and the low breakdown rate, results in significantly reduced dust levels, thus ensuring good operator visibility, and less risk to personnel or environmental contamination in surrounding areas. The low consumption rate and the recyclability, up to 5 times, of the abrasive, also ensure the volume of waste generated for disposal is minimized.

Usage :

Sand Blasting, Waterjet Cutting, Abrasive Grains, Filtering Media

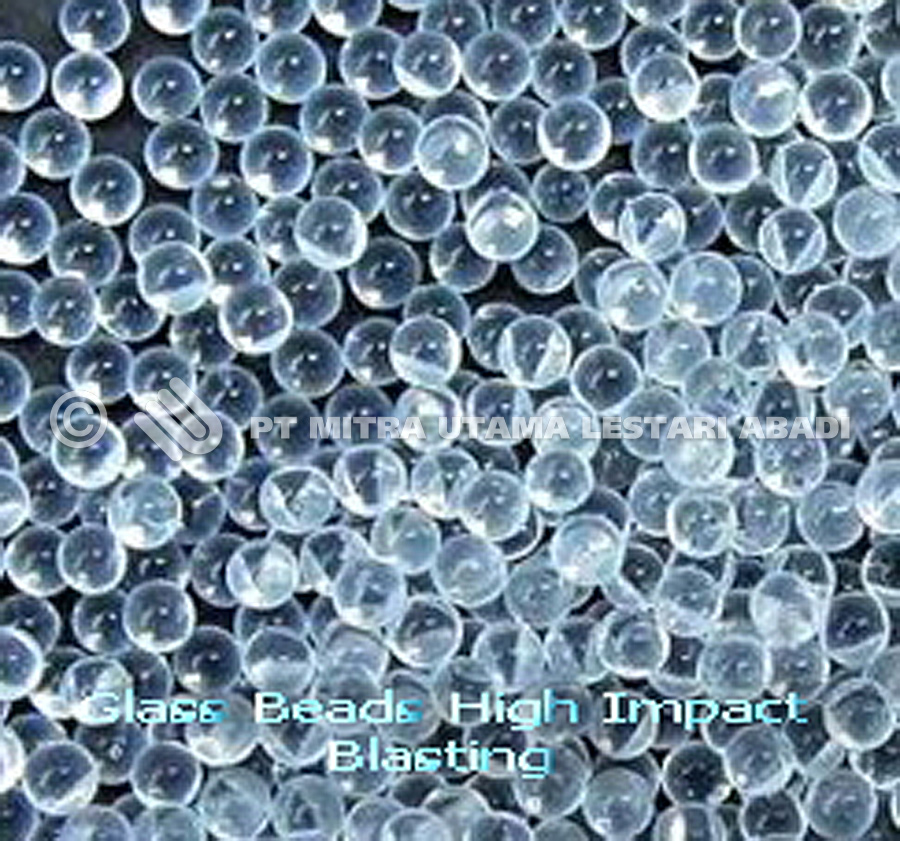

Glass Beads is manufactured from Soda Lima Glass and suitable for blast cleaning, peening, deburring and finishing application in pressure, vaccuum and suction units.

Some applications of glass beads :

- Glass Beads for blasting material

- Glass Beads highway series Intermix

- Glass Beads highway series Drop On

The walnut shell grain can be used in cleaning and blasting Molds, Apparatus, Plastics, Gold and silver jewelry, Glasses, Watches, Golf Club, Barrette, Buttons etc as blasting materials, polishing materials and also can be used in producing Grinding Wheel as the materials of forming air hole.

The walnut shell grain can be used in cleaning and blasting Molds, Apparatus, Plastics, Gold and silver jewelry, Glasses, Watches, Golf Club, Barrette, Buttons etc as blasting materials, polishing materials and also can be used in producing Grinding Wheel as the materials of forming air hole.

Green silicon carbide is well noted as one of nice artificial material , also named emery grain or carborundum , which is produced by high-temperature smelting of electric furnaces such as quartz sand, petroleum coke , and wood chips ,require the addition of salt when producing. specific gravity of 3.20 ~ 3.25, microhardness of 2840 ~ 3320kg / mm2.

The production method of green silicon carbide micropowder is basically the same as that of black silicon carbide, but the requirements for raw materials are different. Green silicon carbide is made of petroleum coke and high-quality silica as the main raw material. It is added with salt as an additive and is smelted by high temperature furnace. The crystals which are smelted have high purity and hardness, and the hardness is between corundum and diamond. Mechanical strength Higher than corundum.

Products Application:

- Solar wafer, semiconductor wafer and quartz chip wire sawing and lapping, bonded and coated abrasive tools

- Stone polishing for processing metal and non-ferrous metal with low tensile strength ,such as:gray pig iron , brass, aluminum ,stone, leather and rubber.

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.

| Brown Alumunium Oxide | White Alumunium Oxide | Silicon Carbide (Black) |

| Garnet | Glass Beads | Walnut Shell |

| Green Silicon Carbide | Monocrystal (Single) Fused Alumina Product |

For further information, you can contact our Sales Engineer, or you can contact us directly or here.