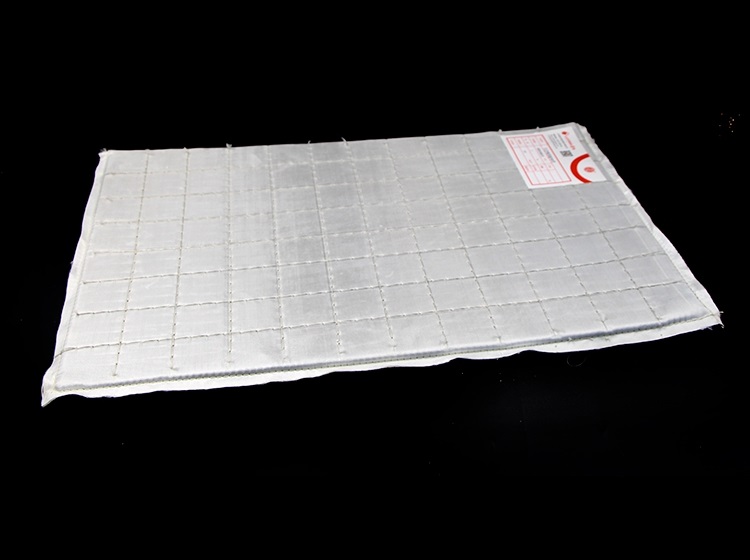

VERMICULATE

Vermiculate is an insulating board material with raw material of Vermiculate and a special binding material.

The Vermiculate advantage :

- Thermal shock resistance, can be used in parts of furnace that are directly related to heat.

- No smoke during heating

- Low Thermal conductivity.

- High electrical resistance

- High thermal resistance

- Good chemical resistance to acids, alkalis and exhaust gases

- Rigid and stable with sufficient mechanical stability

Aplication Area:

Insulation material for furnaces as back up for lining, Boilers, Vessels and tanks

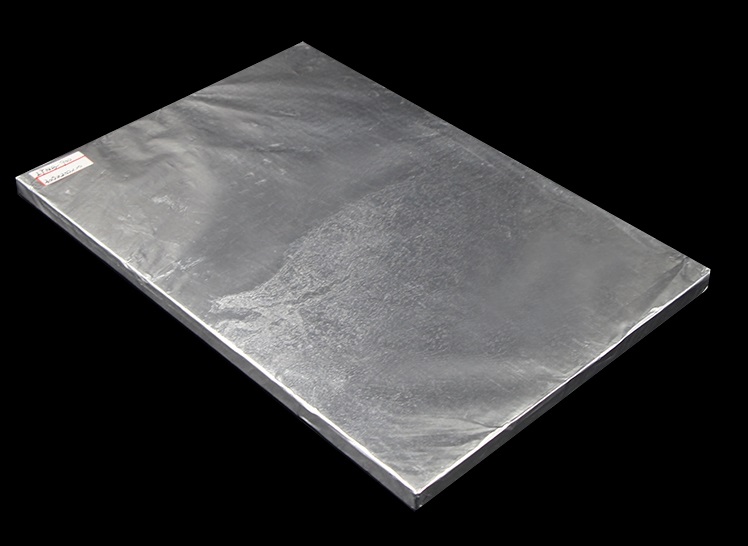

MICROPOROUS (MICROBOARD) INSULATING BOARDS

Microporous (Microboard) Insulating Board is an insulating material that has lowest thermal conductivity. The material is made from nano-porous material using a special binder. This material can use a layer of aluminum foil on one layer, or both layers, and also use PE foil layer on one layer, or both layers.

Physical Properties

| Description |

Microporous Hardboard 60H |

Microporous Hardboard 90H | Microporous Hardboard 105H |

Microporous Softboard 90S |

| Recommended Temperature of Use (°C ) | 600 | 900 | 1050 | 900 |

| Density (kg/m3 ) | 300/320 | 280/300 | 320 | 260/300 |

| Modules of Rupture (MPa) | >0.15 | >0.15 | >0.15 | - |

| Compressive Strength

<MPa 10% relative deformation) |

>0.3 | >0.3 | >W.3 | - |

| Permanent Linear Shrinkage (%) | 600 oC x 24h <2.0 | 900° C x 24h <2.0 | 1050 °C x24h <2. 5 | 900 °C x 24h <2.0 |

| Thermal Conductivity (W/m·K) | ||||

| 100 °C | 0.022 | 0.020 | 0.022 | 0.022 |

| 200 °C | 0.024 | 0.023 | 0.024 | 0.025 |

| 300 °C | 0.028 | 0.026 | 0.031 | 0.027 |

| 400 °C | 0.029 | 0.027 | 0.036 | 0.029 |

| 500 °C | - | 0.033 | 0.040 | 0.033 |

| 600 °C | - | - | 0.048 | - |

| Covering Material | Aluminum Foil/PE Foil/Glass Fiber Cloth | Glass Fiber Cloth | ||

| Standard Size (mm) | 600x400x(10-50) | |||

| 1000x500x(1-050) | ||||

The advantages of Microboard :

- Has the lowest thermal conductivity of all insulating materials

- Has high heat resistance

- Free from dust on the surface

- Machining process if necessary

Application Area:

- Back up lining forfurnace at Foundry, Ceramic kilns, glass furnaces and Chemical plants

- Thermal insulation of steel casting ladles and casting facilities

- Thermal insulation of household appliances like boilers, hearth and night storage heaters

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.