Garnet particles are sub-angular in shape resulting in extremely fast cutting rates and low abrasive consumption. The high specific gravity of the abrasive grains, and the low breakdown rate, results in significantly reduced dust levels, thus ensuring good operator visibility, and less risk to personnel or environmental contamination in surrounding areas. The low consumption rate and the recyclability, up to 5 times, of the abrasive, also ensure the volume of waste generated for disposal is minimized.

Application :

Sand Blasting, Waterjet Cutting, Abrasive Grains, Filtering Media

Industries that use include:

Blast/Paint Contractor, Granite/Stone Cutting, Marine, Shipbuilding Repair; Oil and Gas/Pipeline; Plant Maintenance; and Steel Fabrication/Manufacturer.

Size :

| Grades | 100 | 80 | 60 | 30/60 | 20/40 | 16/20 | 10/20 | Un-screened |

| Micron | 150 | 180 | 250 | 250-600 | 425-850 | 850-1180 | 850-2000 | 106-850 |

| Inch | 0.006 | 0.007 | 0.009 | 0.009-0.023 | 0.016-0.023 | 0.033-0.046 | 0.033-0.078 | 0.04-0.033 |

Mesh 12/40 :

One of the most preferred products for multi-media-water-filtration systems. It can also be used for specialized application where excessive surface profiling is required or very high built coating systems are to be removed.

Surface Profile: 100-150 microns

Mesh 20/40 :

Widely used to remove thick coating layers.

It is an abrasive that can be utilized for heavy-duty coating removal. It's recyclability and nominal production rates makes it one of the most preferred repair-grade abrasives.

Surface profile: 75-100 micron.

Mesh 20/60:

It is the most cost effective and excellent abrasive of its kind. Its repeatability makes it suited for fast and efficient removal of existing coatings when compared to other traditionally used abrasive medium.

Surface profile: 50-90 microns.

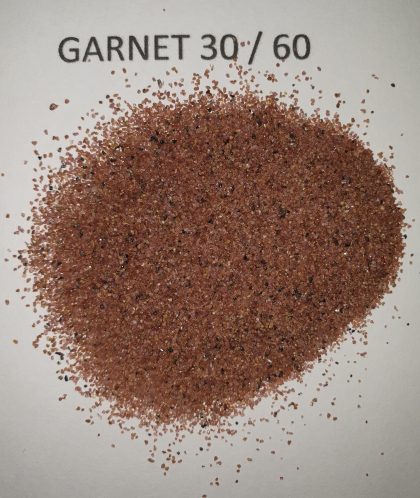

Mesh 30/60 Mesh :

It is the most popular garnet blasting abrasive grade and perfect for all types of blasting applications including, removing existing coating, rust and other contamination. It is an ideal choice for superior surface preparation for new steel prior to tank coating, for pipelinesboth

internal and external, fabricated steel and structures, etc. Also used for effective removal of mill scale, it is the most preferred as a Slurry- Blast Grade and High Pressure Hydro-Blasting Abrasive.

Surface Profile: 50-75 microns.

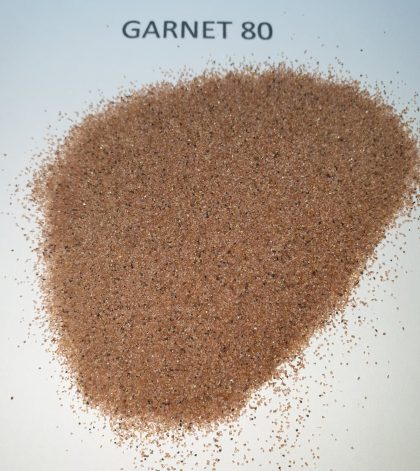

80 mesh :

Possessing highest efficiency on new steel/mill scale due to highest grain count per weight/volume makes it an ideal choice for surface preparation of Aluminium and non-ferrous surfaces.

Mesh 120 :

Utilized for surface preparation of stainless steel and Aluminum where minimum surface roughness is desired, this abrasive medium can be used on a variety of pliable and synthetic products too.

| Brown Alumunium Oxide | White Alumunium Oxide | Silicon Carbide (Black) |

| Garnet | Glass Beads | Walnut Shell |

| Green Silicon Carbide | Monocrystal (Single) Fused Alumina Product |

For further information, you can contact our Sales Engineer, or you can contact us directly or here.