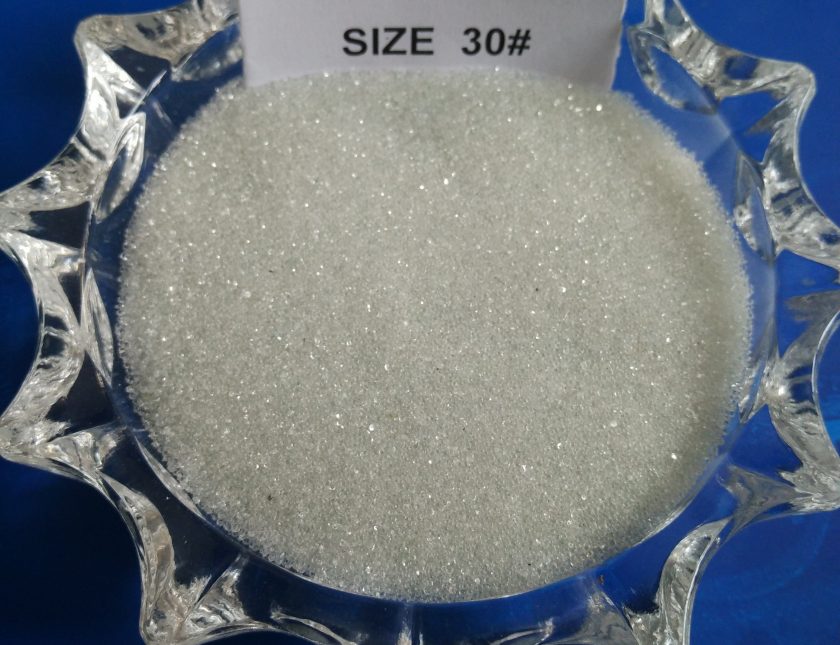

Glass Beads for Sand Blasting No 3

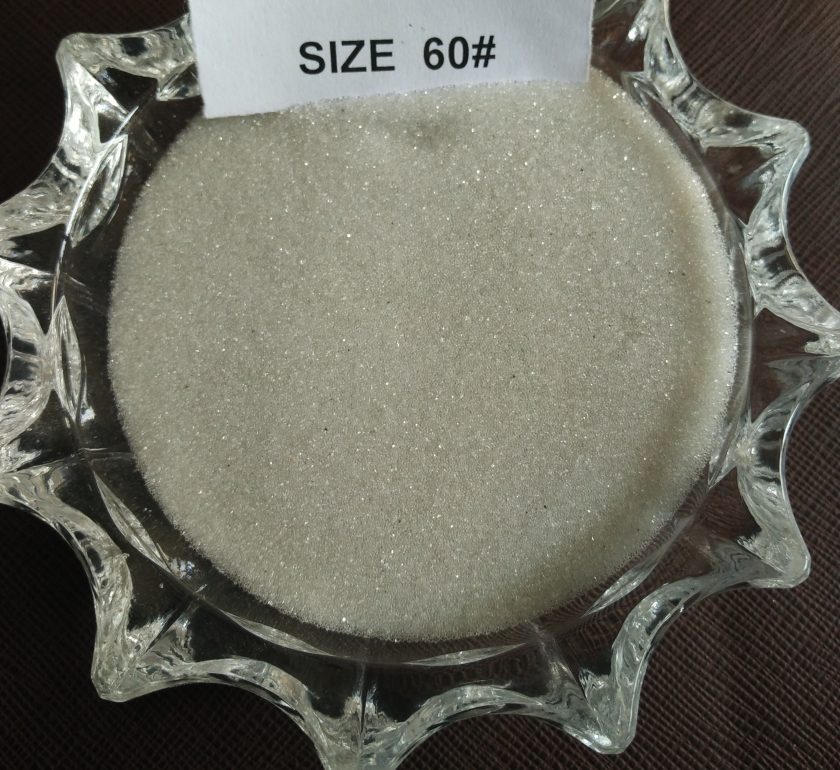

Glass Beads for Sand Blasting No 8

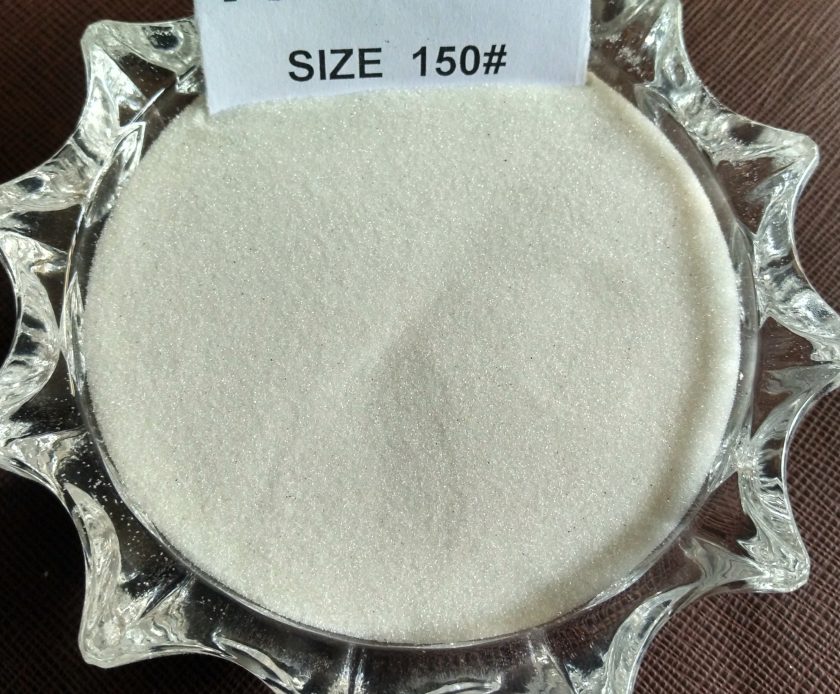

Glass Beads for Sand Blasting No 10

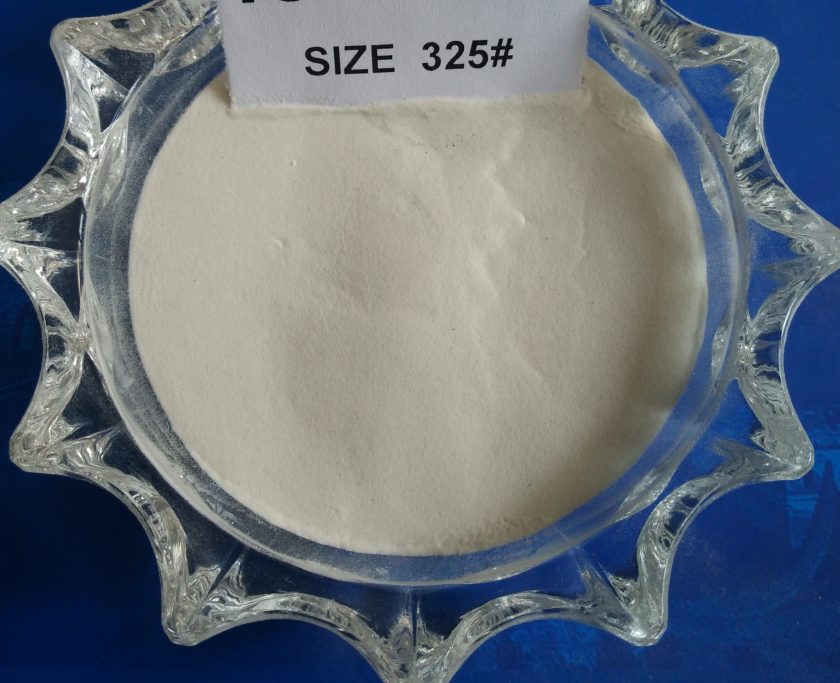

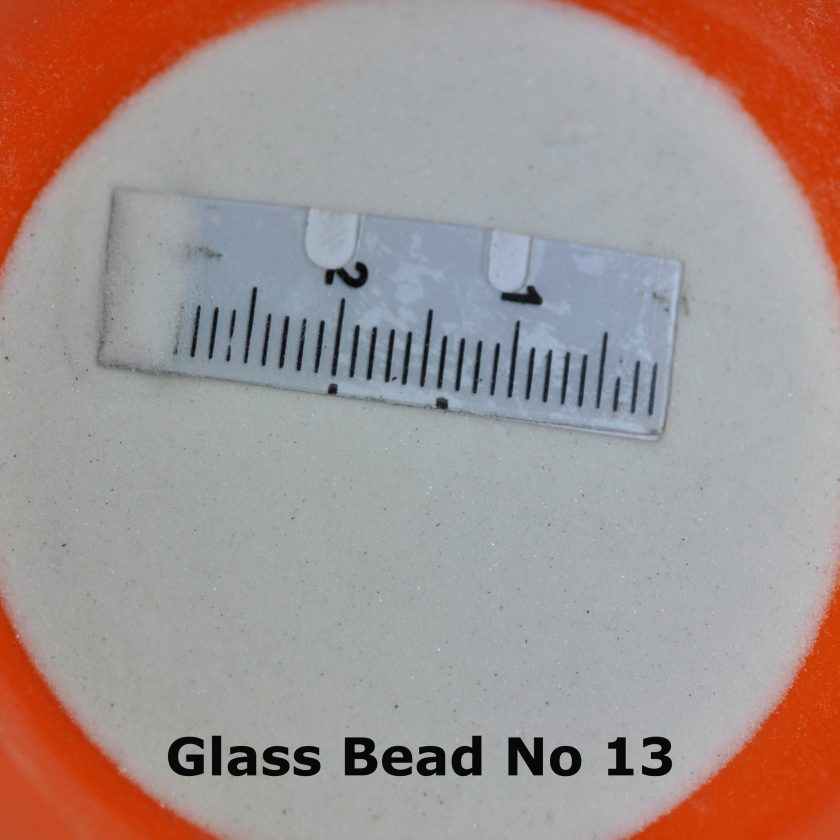

Glass Beads for Sand Blasting No 13

Glass Beads is manufactured from Soda Lima Glass and suitable for blast cleaning, peening, deburring and finishing application in pressure, vaccuum and suction units.

Applications on blasting process are extremely diverse and include cleaning, removal of dirt, grease, oxide etc. It cleans the surface of metal parts without changing tolerances.

Other appliations :

- For cleaning the moulds in die-casting, metal forging, extrution glass, the rubber and thermo plastic.

- To clean the dirt layer on the piston chamber.

- To give a smooth and bright finished to surgical equipment and automotive parts.

- To clean the coil, rotor brushes, and other parts of a generator overhaul.

Standard Chemical Analysis

| SiO2 | 71 – 73 % (not less than 70%) |

| N2O | 13 – 15 % |

| CaO | 8 – 10 % |

| MgO | 3 – 5 % |

| Al2O3 | 0.5 – 2.0 % |

| K2O | 0.2 – 0.6 % |

Size based on MIL-G-9954A

| Item No | Description | Size | US Sieve | Screen | Size (micron) |

|---|---|---|---|---|---|

| NEML03 | Glass Powder | 3 | 20 to 30 | 20 to 30 | 850 to 600 |

| NEML04 | Glass Powder | 4 | 30 to 40 | 30 to 40 | 600 to 425 |

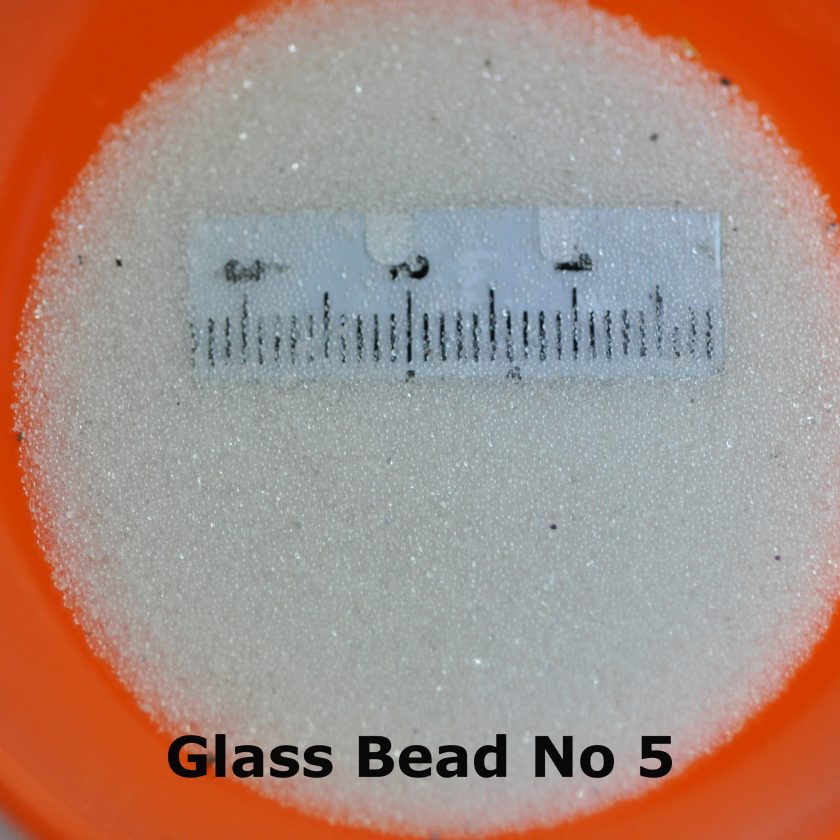

| NEML05 | Glass Powder | 5 | 40 to 50 | 40 to 50 | 425 to 300 |

| NEML06 | Glass Powder | 6 | 50 to 70 | 50 to 70 | 300 to 212 |

| NEML07 | Glass Powder | 7 | 60 to 80 | 60 to 80 | 250 to 180 |

| NEML08 | Glass Powder | 8 | 70 to 100 | 70 to100 | 212 to 150 |

| NEML09 | Glass Powder | 9 | 80 to 120 | 80 to120 | 180 to 125 |

| NEML10 | Glass Powder | 10 | 100 to 170 | 100 to 170 | 150 to 90 |

| NEML11 | Glass Powder | 11 | 120 to 200 | 120 to 200 | 125 to 75 |

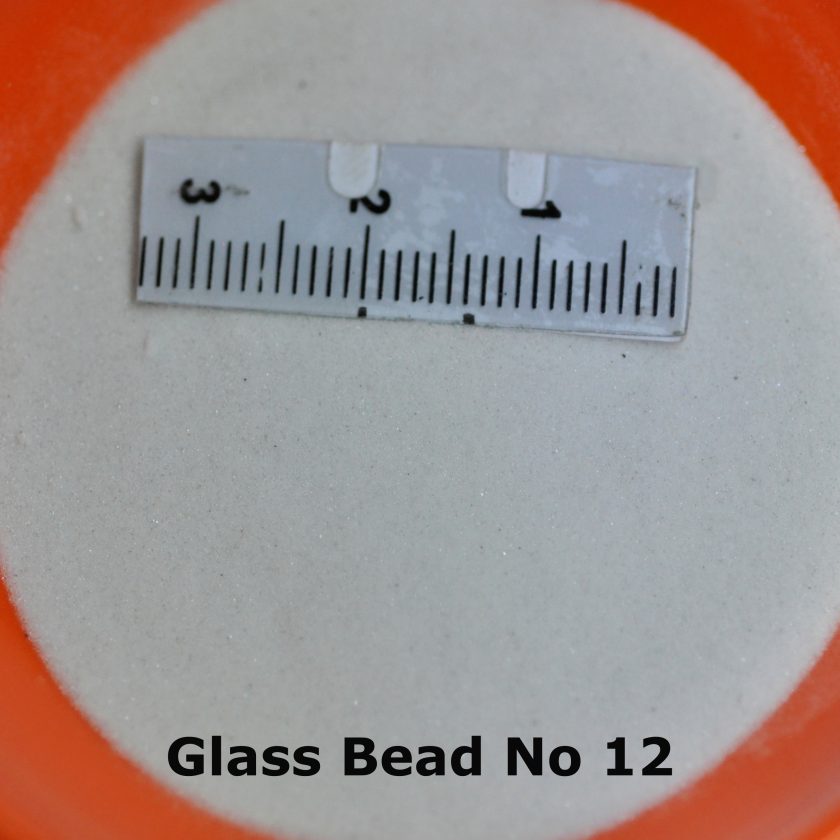

| NEML12 | Glass Powder | 12 | 140 to 230 | 140 to 230 | 106 to 63 |

| NEML13 | Glass Powder | 13 | 170 to 325 | 170 to 325 | 90 to 45 |

Grain size comparison – Glass Bead

No 3

No 8

No 13

No 4

No 11

No 5

No 11

No 7

No 12

| Brown Alumunium Oxide | White Alumunium Oxide | Silicon Carbide (Black) |

| Garnet | Glass Beads | Walnut Shell |

| Green Silicon Carbide | Monocrystal (Single) Fused Alumina Product |

For further information, you can contact our Sales Engineer, or you can contact us directly or here.