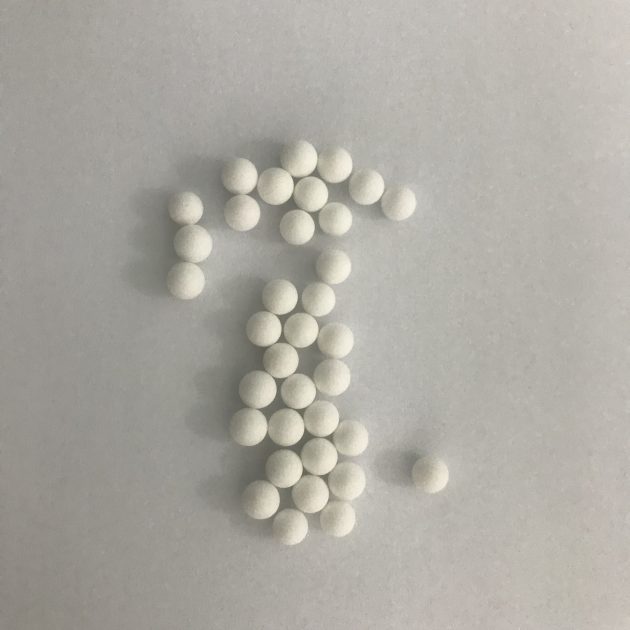

Yttrium Stabilized Zirconia Beads

Yttrium Stabilized Zirconia beads used in ultra-fine grinding and dispersion of materials requiring ''zero pollution', high viscosity and high hardness, such as: non-metallic minerals, pesticides, electronic ceramics, magnetic materials, titanium dioxide, medical supplies, pigments, dyes, inks, special chemical industry, etc.

Product Specification:

| ZrO2 (%) | 95 +/ -5 | 80 +/- 5 |

| Moh's | 8 | 9 |

| Gravity Density | 6.0 min | 6.1 min |

| Wear | 2ppm | 4ppm |

| Diameter | 1-50mm | 1-10mm |

Applications:

- Electronic material (such as BaTiO3, BaCO3), magnetic bands superfine grinding.

- Paint, pigment, coatings dispesing and superfine grinding.

- Ceramic glaze (Zirconia sand) superfine grinding.

- Medication, cosmetic dispersing and superfine grinding.

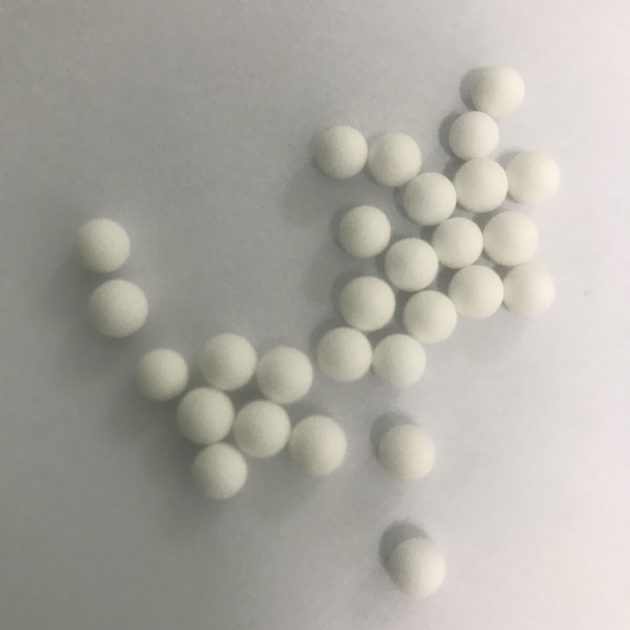

Zirconium Silicate Beads

Zirconium Silicate bead is composed of silicon oxide and zirconia with the same molar ratio. The formula is ZrSiO4. It is made by advanced technique of titrating in electrolyte and sintering at high temperature. The microstructure inside the bead is composed of dense zirconium silicate particles, which rejects the capillary gap and cavity and avoids the separation of crystal phase and glass phase.

Application:

Due to high specific gravity, low wear, good corrosion resistance, good compression resistance and other advantages, the zirconium silicate beads are widely used in medicine, chemical industry, ink, painting, food, electronic ceramics, cosmetics, etc. It is suitable for fine grinding and dispersing of horizontal sand mill, vertical sand mill, centrifugal sand mill, nanometer sand mill and other equipment.

Zirconia Ceramic Balls

The zirconia ceramic ball has a pearly luster and smooth surface. Using micron and sub-nanometer zirconia powder as raw material, yttrium oxide or cerium oxide as stabilizer, then by titrate or dry isostatic pressing into dry type, and by high temperature calcination process.

Zirconia ceramic ball has high strength, high toughness, good wear resistance, high temperature resistance, corrosion resistance, high stiffness, non - magnetic, electrical insulation at room temperature. With a temperature of 600℃, the strength and hardness of zirconia balls can remain unchanged. In addition, the density of it is 6.00g/cm3, and its thermal expansion rate is close to that of metal, so it can be used in conjunction with metal.

Application:

Zirconia ceramic balls are widely used for the ultra-fine grinding and dispersion of heavy calcium carbonate, kaolin, titanium dioxide, mica, paint, ink, pigments, magnetic materials and other materials.

Ceramic Sandblasting Media

Ceramic sandblasting media is one kind of economical and excellent material for sandblasting especially stead of White aluminium oxide (white corundum), which especially designed for sandblasting application, as well as cutting disc, color ceramic sandblasting material present similar performance with white aluminium oxide, but much cheaper then it.

Physical property :

Crystal size (um) : 600-1400

True density (ɡ/cm³) : > 3.90

Bulk density (ɡ/cm³) : 1.40-1.95

Hardness (Hv) : 2200-2300

Available Grit size : #16 to #220

Alumina Ball

Alumina Ball (Alumina grinding balls) refer to materials such as bauxite, roller powder, industrial alumina powder, high-temperature calcined alpha alumina powder, etc. Mainly used for finishing and deep processing hard materials of different types of ceramics, glazes, glass and chemical factories. Its grinding efficiency and wear resistance are much better than ordinary pebble or natural pebble.

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.