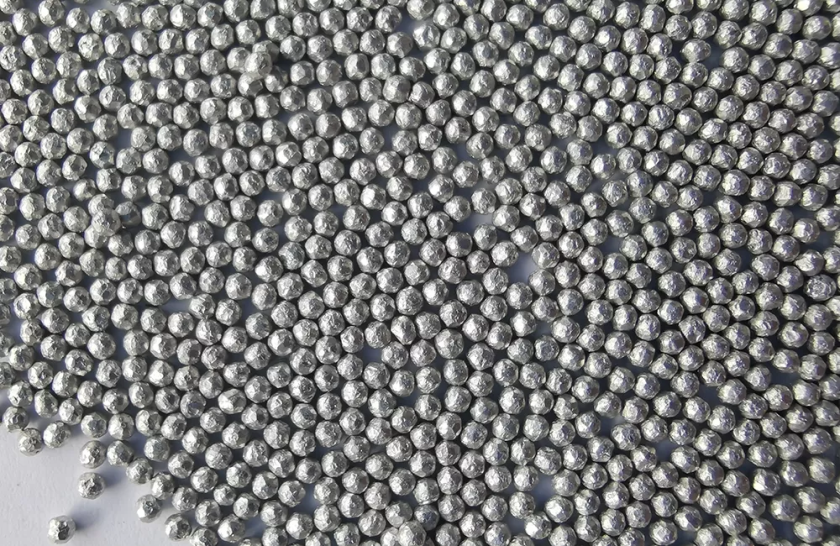

Aluminium Round Shot is used mainly for sand removal, deburring and deflashing of non ferrous components. Aluminum Round Shot is used in blasting treatment of aluminum and zinc workpiece surface, obvious whitening effect on workpiece surface. It is applied in shot blasting treatment to inhere the obvious whitening effect.

Excellent abrasive and descale effect for the deluxe production small scale mild aluminum. Predominantly used for sand, stain and burr removal and produce a glossy finish on the component. It also used in wheel blast applications where a “soft impact” is desired during the blast process.

It is the ideal material for cleaning and reinforcing the surface of nonferrous metal casting parts. Made from superior grade Aluminum, these are highly durable and long lasting.

Application :

- Shot peening for steel and aluminum

- Shot blasting for steel and aluminum

- Deburring and deflashing for aluminum and zinc castings made by die castings and gravity casting systems

- Blast cleaning of cast steel shot:Used for blast cleaning of casting, die-casting, forging, sand removal of casting, steel plate, H type steel, steel structure.

- Rust removal of cast steel shot:Rust removal of casting, forging, steel plate, H type steel, steel structure, descaling of forging.

- Removal of sand from sand castings. Removal of parting lines and stains from non ferrous castings. Removal of water wrinkle from aluminium die castings and providing a luster satin type finish.

Chemical composition :

| Al | Si | Mn | Fe | Mg | Cu |

|---|---|---|---|---|---|

| 99.70% Min | 0.09% Max | 0.01% max | 0.1% max | 0.01% max | 0.04% max |

Mechanical properties :

| Hardnes | 65 - 125 HV |

| Density | 2.7 kg/m3 |

| Microstructure | Deformed α |

| Usage | 6500 Times |

| Form | Shiny and column |

| Size | 0.6mm, 0.8mm, 1.0mm, 1.2mm dan 1.50mm |

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.