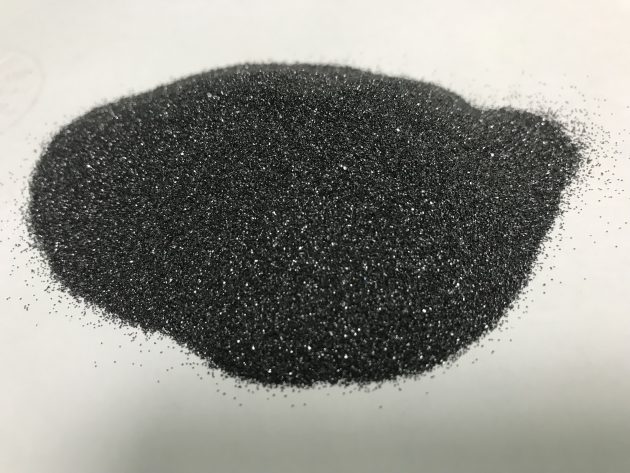

Silicon Carbide Blasting Media is an abrasive materials manufactured by combining silica sand with carbon in an electric resistance furnace. It is chemically inert and is also harder than any of the alumina products.

It is ideal for applications where rapid or aggressive surface treatment is required.

There are two basic types of silicon carbide, namely black silicon carbide and green silicon carbide, both of which belong to α-SiC.

Black silicon carbide contains about 98.5% SiC, and its toughness is higher than that of green silicon carbide. It is mostly used for processing materials with low tensile strength such as glass, ceramics, stones, refractory, cast iron and non-ferrous metals.

Green silicon carbide contains about 99% SiC or more, and with good self-sharpening. Most of it is used for processing cemented carbide, titanium alloy and optical glass, as well as honing cylinder liners and finishing high-speed-steel tools. In addition, there is cubic silicon carbide, which is a yellow-green crystal made with a special process.

Applications :

| 1. | The pretreatment of workpieces before coating, plating and bonding. Silicon carbide, as a blasting media can remove dirt such as rust on the surface of the workpiece, and create the toughness required to "lock" the coating. In addition, the different degrees of toughness can be achieved through the exchange of different particle size of abrasive, which greatly improve the binding force between coating and metal base. |

| 2. | Cleaning and polishing the rough surface of casting and forging parts and the workpiece after heat treatment. Silicon carbide for sandblasting can clean up the dirt on the surface of casting and forging parts and the workpiece after heat treatment, such as oxide skin, oil and other residues. In addition, it can polish the surface of the workpiece to improve the smooth finish and play a role of beautification. |

| 3. | Burr cleaning and surface beautification. Silicon carbide can clean the tiny burr on the surface of the workpiece, and make the surface of workpiece more flat, eliminate the harm of burr, raise the grade of the workpiece. Besides, sandblasting can produce a small rounded corner on the surface of the workpiece to make it more beautiful and more precise. |

| 4. | Improve the mechanical properties of parts. After the silicon carbide sandblasting, the uniform fine concave-convex surface will be produced on the surface of parts, so that the lubricating oil can be stored to improve the lubrication conditions, and reduce the noise so as to improve the service life of the machinery. |

| 5. | Light decoration. |

| a. Polishing the surface of the workpiece to make the surface more beautiful. | |

| b. Making the workpiece achieve the requirement of smooth and non-reflective, that is, to achieve a certain surface roughness. For some special purpose workpieces, silicon carbide sandblasting can achieve different reflective or matte effects. Such as stainless steel workpiece, the matte processing of wooden furniture, the patterns of ground glass's surface, and the roughening processing of cloth’ surface. |

Chemical composition :

| SiC | 98.30 % |

| SiO2 (not free) | 0.35 % |

| Si | 0.67 % |

| Fe2O3 | 0.05 % |

Technical specifications :

| Shape | Angular |

| Color | Black |

| Weight (gravity) | 3.22 |

| Density | 3.0 – 3.5 g/cc |

| Hardness | Mohs 9 - 9.5 |

Size :

Grit 12, 14, 16, 20, 24, 30,36,46, 54, 60, 70, 80, 90,100, 120, 150, 180, 220

| Brown Alumunium Oxide | White Alumunium Oxide | Silicon Carbide (Black) |

| Garnet | Glass Beads | Walnut Shell |

| Green Silicon Carbide | Monocrystal (Single) Fused Alumina Product |

For further information, you can contact our Sales Engineer, or you can contact us directly or here.