Why ZSI ?

High and increasing amount of secoundary and/or alternative fuel!

─ High and increasing amount of secoundary and/or alternative fuel creates high chemical load (e.g. chlorids, alkalis). It needs refractory which is Resistance against various chemical attacks

─ High and increasing amount of secoundary and/or alternative fuel creates H2O containing atmospheres. Chemical reaction between H2O and SiC create passive increasing volume.

Passive oxidation of SIC

SiC (s) + 2 H2O (g) -> SiO2 (s) + CH4 (g) [passive], increasing of volume

It needs refractory which is Lower SIC contents, SIC protection“

─ High and increasing amount of secoundary and/or alternative fuel creates more unwanted deposits and build up. Use of various cleaning methods (e.g.: water- and air-canons, Cardox).

It needs refractory which are Mechanical resistance, Abrasion resistance & Thermomechanical resistance

Necessity of a chemical, mechanical and thermomechnical resistant material

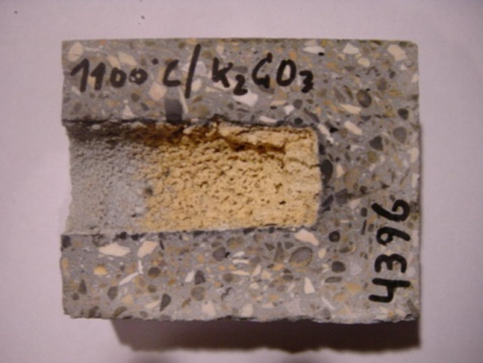

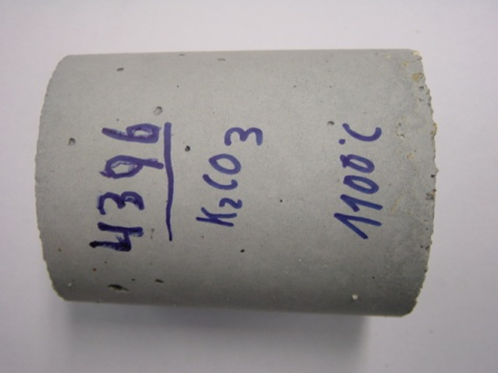

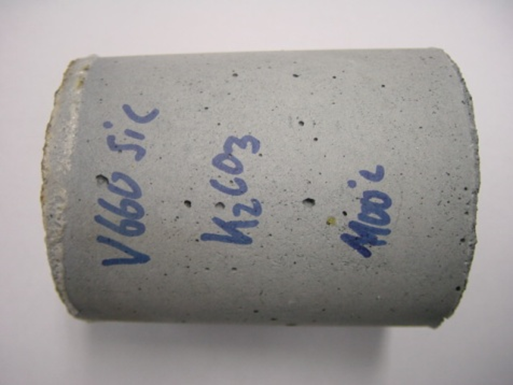

Extreme good resistance against alkali attack, also in H2O containing atmosphere

Standard LC Castable

ZSI Product - Series

SiC Product

ZSI Product

|

Al2O3 (%) |

SiO2 (%) |

(%) |

AT (°C) |

CCS 1450 °C (MPa) |

(t/m3) | |

| Supergun 63 ZSI | 63 | 10 | 11 (ZrO2), 7 (SiC) | 1450 | 100 | 2,7 |

| Refcast V663 ZSI | 63 | 12 | 12 (ZrO2), 7 (SiC) | 1500 | 150 | 3,0 |

| TSR | Alkali resistance |

Abrasion resistance (ASTM) |

|

| Supergun 63 ZSI | ++++ | ++++ | < 10 cm³ |

| Refcast V663 ZSI | ++++ | ++++ | < 4 cm³ |

➔ Now Also available as fast heat up / Sol-Gel Version

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.