Refko Veneering System

Refko Recovery is A state-of-the-art fast Refractory lining repair for emergencies and for reduction of shutdown time in cement industries. To avoid a long emergency- and repair-stop caused by brick problems. The installation of Refko Recovery helped the plant re-start the kiln fast and to run the kiln save until the annual and planned shutdown.

Worldwide, the demand for cement remains at a high level. Higher quantities of cement have to be produced by fewer cement kilns, and a high degree of operational safety is required. Downtimes must be shortened and kept to a minimum, and unscheduled downtimes must be completely avoided. Emergency situations, such as sudden hot spots that arise on the rotary tube, have in the past often led to longer unscheduled downtimes in order to replace the worn areas with new bricks. It often happens that in such emergency situations, not enough bricks are available for repair and are not easily procured on such short notice. Plants may also find that there are no skilled or trained installation personnel or required installation machines (e.g. DAT devices) available at the time.

In this case, emergency solutions may be required, such as cooling or other measures in the running process. Not infrequently, however, the continued operation of a kiln with brick damage in the rotary tube then leads to serious subsequent damage, for example deformation of the steel shell, problems in the kiln drive areas, etc. Therefore, the process reliability of the kiln system is at stake. This is where the REFKO Recovery System comes into play.

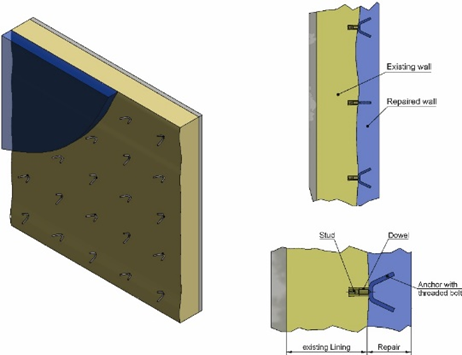

This material and system development allows a hot spot situation (caused by brick damage) on the rotary kiln to be quickly rectified and enables safer operation of the kiln until a planned, usually annual, shutdown. The special binding system and selected material composition of the REFKO Recovery System provides a good bond with the existing worn out lining. The installation can be completed with classic dry gunning machines, which are available worldwide.

Easy and fast repair refractory problems that pop up suddenly

- Fast recovery of lining by installation on top of “old“ material

- No special heating up schedule needed

- Fast return of kiln into operation mode

- No long unplanned shutdown

- Save Recovery of lining until next planned shutdown

- Save Recovery of lining until next planned shutdown

Save Recovery of lining until next planned shutdown.

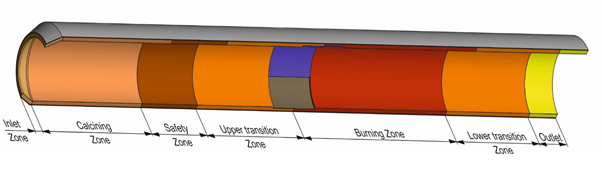

Sketch of a rotary kiln.

Premature wear of MgO/Spinel bricks.

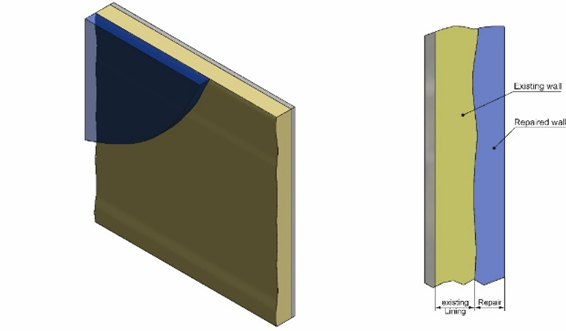

Lining Sketch with Refko Recovery Veneering

With the REFKO Recovery MG products based on Mgo/Spinel, successful and long-lasting repairs can be carried out in the rotary kiln area.

Lifetime was minimum 3-4 month and could have been longer.

Reference Customers:

- Heidelberg Cement AG Paderborn Germany

- Heidelberg Cement AG Hannover Germany

- Schretter & Cie GmbH - Austria

News & Publication by Refko Feurfest Germany

- Saving Time and Money by Herbert Hönl, Refko Feuerfest GmbH, Germany on World Cement 2015

- Relieving Mechanical & Chemical Stress by Herbert Hönl, Refko Feuerfest GmbH, Germany on World Cement 2014

- In the Line of Fire by Herbert Hönl, Refko Feuerfest GmbH, Germany on World Cement 2011

- Ready for Rapid Recovery & Repair by Herbert Hönl, Refko Feuerfest GmbH, Germany on World Cement September 2021

Please visit website www.refko.de

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.