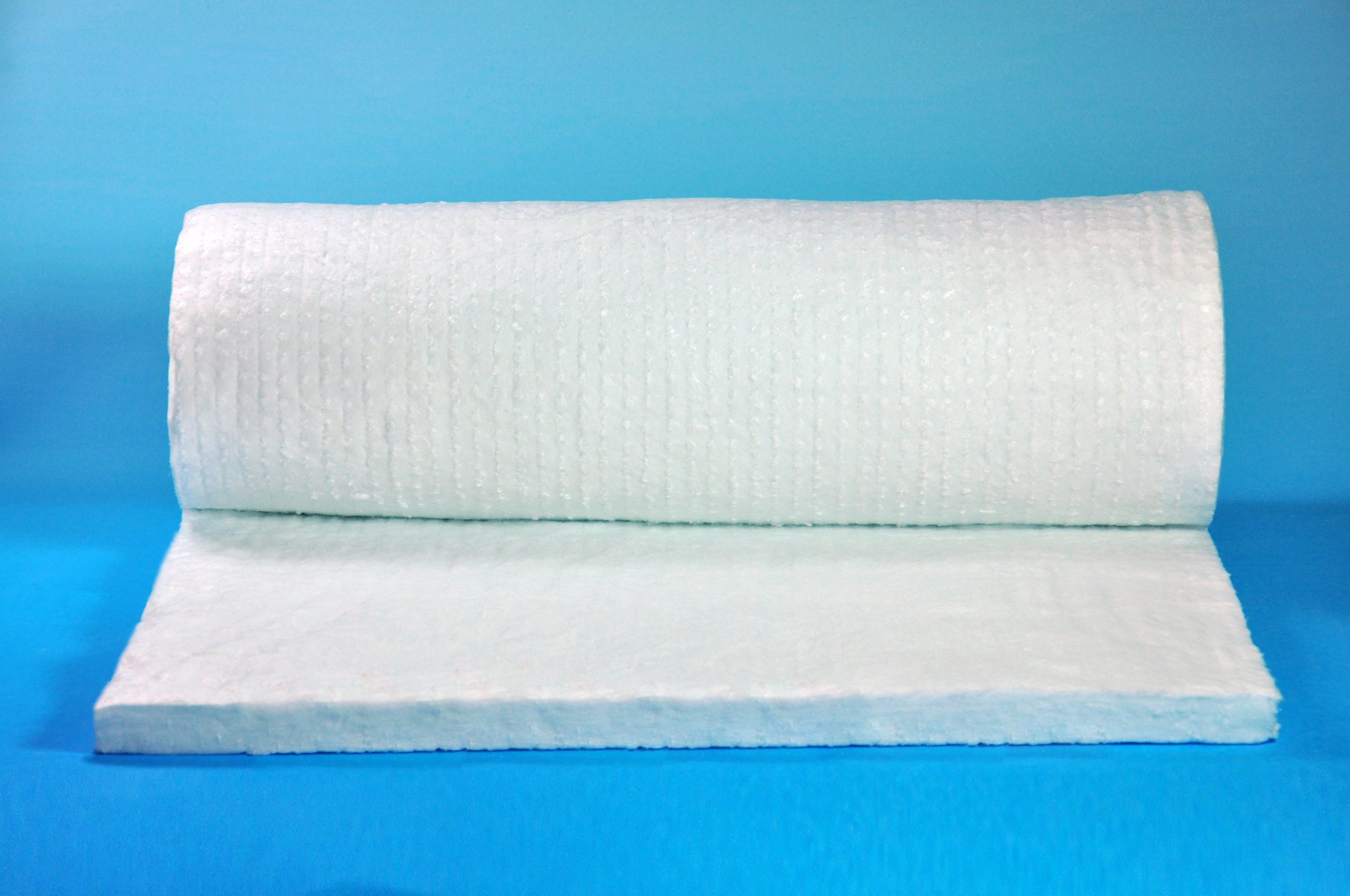

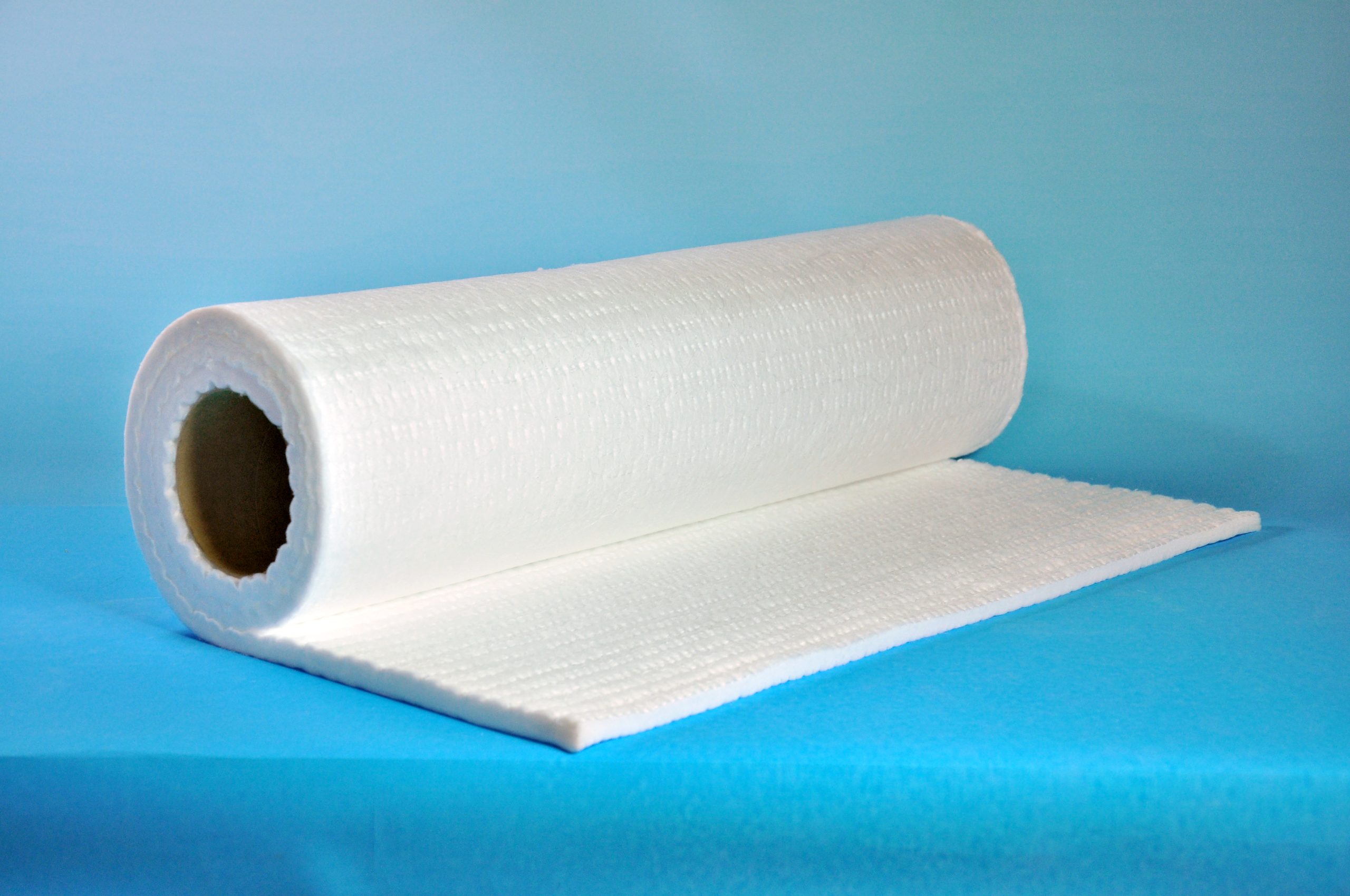

CERAMIC FIBER BLANKET is made of special ceramic long-fiber that is produced by the melting of very pure raw materials in double surface needling process without binders and with good stability in a large range of temperature. The process of double surface needling increases interweaving and tensile strength.

TYPICAL APPLICATIONS OF BLANKET

Acoustical service and fire protection, Soaking pit seals, Expansion joint packing, Linings and seals for oven and furnace, High temperature gasketing, Process furnace linings: heaters, reformers, ethylene cracking, heat-treating, etc.

Technical Specification:

| Ceramic Fiber Blanket 1100°C | Ceramic Fiber Blanket 1260°C | Ceramic Fiber Blanket A 1400°C | Ceramic Fiber Blanket Z 1400°C | ||

| Working Temp Rating (°C) | 1100 | 1260 | 1400 | 1400 | |

| Continuous Use Limit (°C) | 1000 | 1100 | 1200 | 1350 | |

| Colour | White | White | White | White | |

| Density (Kg/m3) | 64/96/128 | 64/96/128 | 128/160 | 128/160 | |

| Permanent Linear Change (%) at (24h.128Kg/m3) | -3 (1000°C) | -3 (1100°C) | -3 (1200°C) | -3 (1350°C) | |

| Thermal conductivity (W/m.K)

(Density 128 Kg/m3) |

0.09(400°C) | 0.09 (400°C) | 0.12 (600°C) | 0.16 (800°C) | |

| 0.16(800°C) | 0.16 (800°C) | 0.2 (1000°C) | 0.20 (1000°C) | ||

| Tensile Strength (MPa) | 0.04 | 0.04 | 0.04 | 0.04 | |

| Chemical Analysis(%) | |||||

|

|

Al2O3 | 46 | 47-49 | 52-55 | 39-40 |

| Al2O3+SiO2 | 97 | 99 | 99 | * | |

| Al2O3+SiO2+ZrO2 | 99 | ||||

| ZrO2 | 15-17 | ||||

| Fe2O3 | <1.0 | 0.2 | 0.2 | 0.2 | |

| Na2O+K2O | <=0.5 | 0.2 | 0.2 | 0.2 | |

| Standard Sizes (mm) | 7200/3600×600/610×12.5-50. Other sizes available upon request | ||||

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.