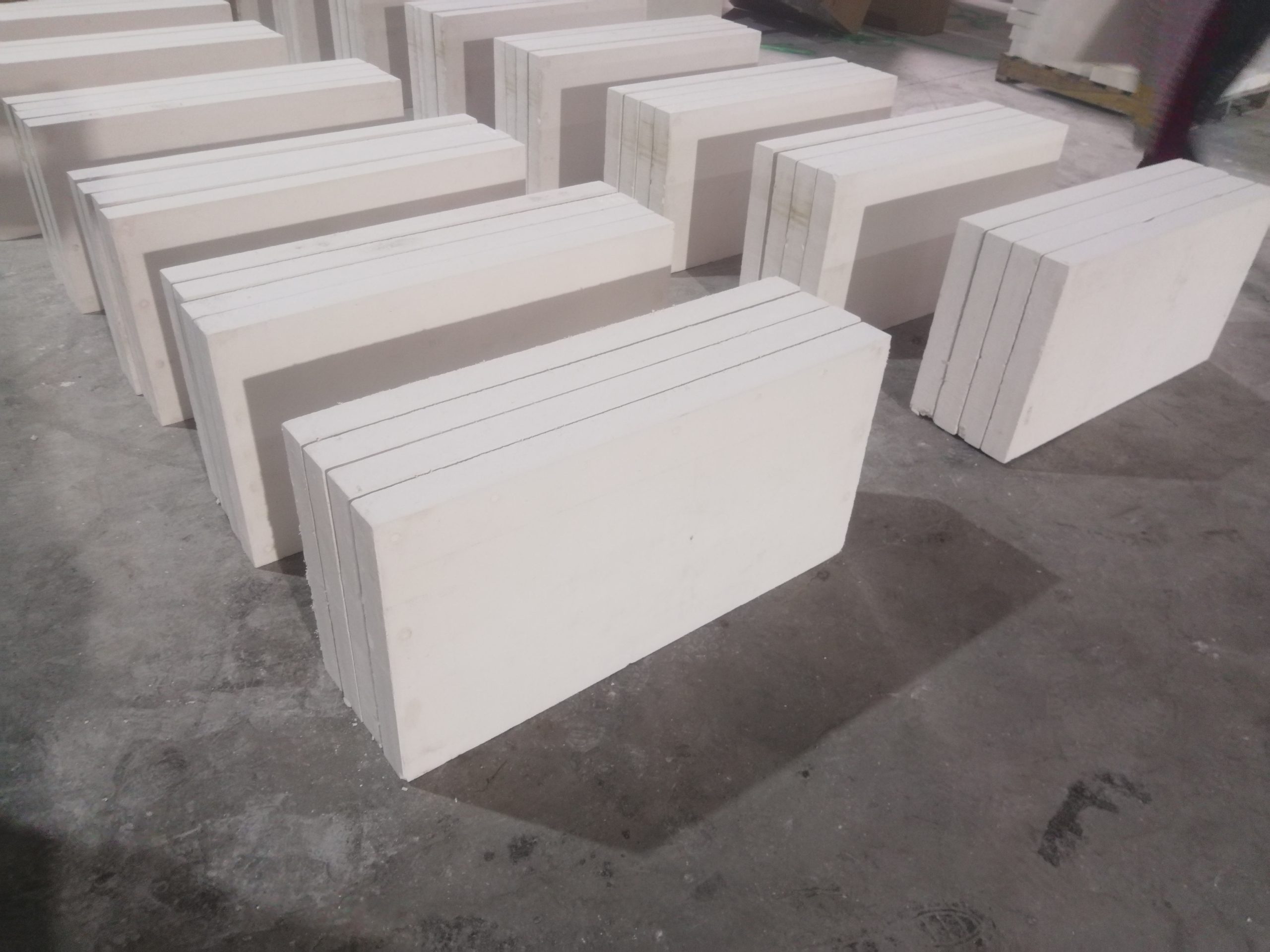

It consist of Dense Calcium Silicate Insulating Boards and Light-weight Calcium Silicate Insulating Boards, Vermiculite Insulating Boards, Vacuum-Formed Board, and etc.

Calcium Silicate -1000 use the raw material of Xonotlite and reinforced with galss fibre. Calcium Silicate -1000 contains no asbestos . It is a high efficient energy-saving material with temperature limited 1050 oC. Characterised by low bulk density, high specific strength, superior heat resistance, outstanding thermal insulation, excellent durability, chemical corrosion resistance, easy to be cut by saw and easy installation, calcium silicate can be widely used for the insulation of industrial kiln.

Calcium Silicate – 1000 has variant density between 200 kg/m3 - 350 kg/m3.

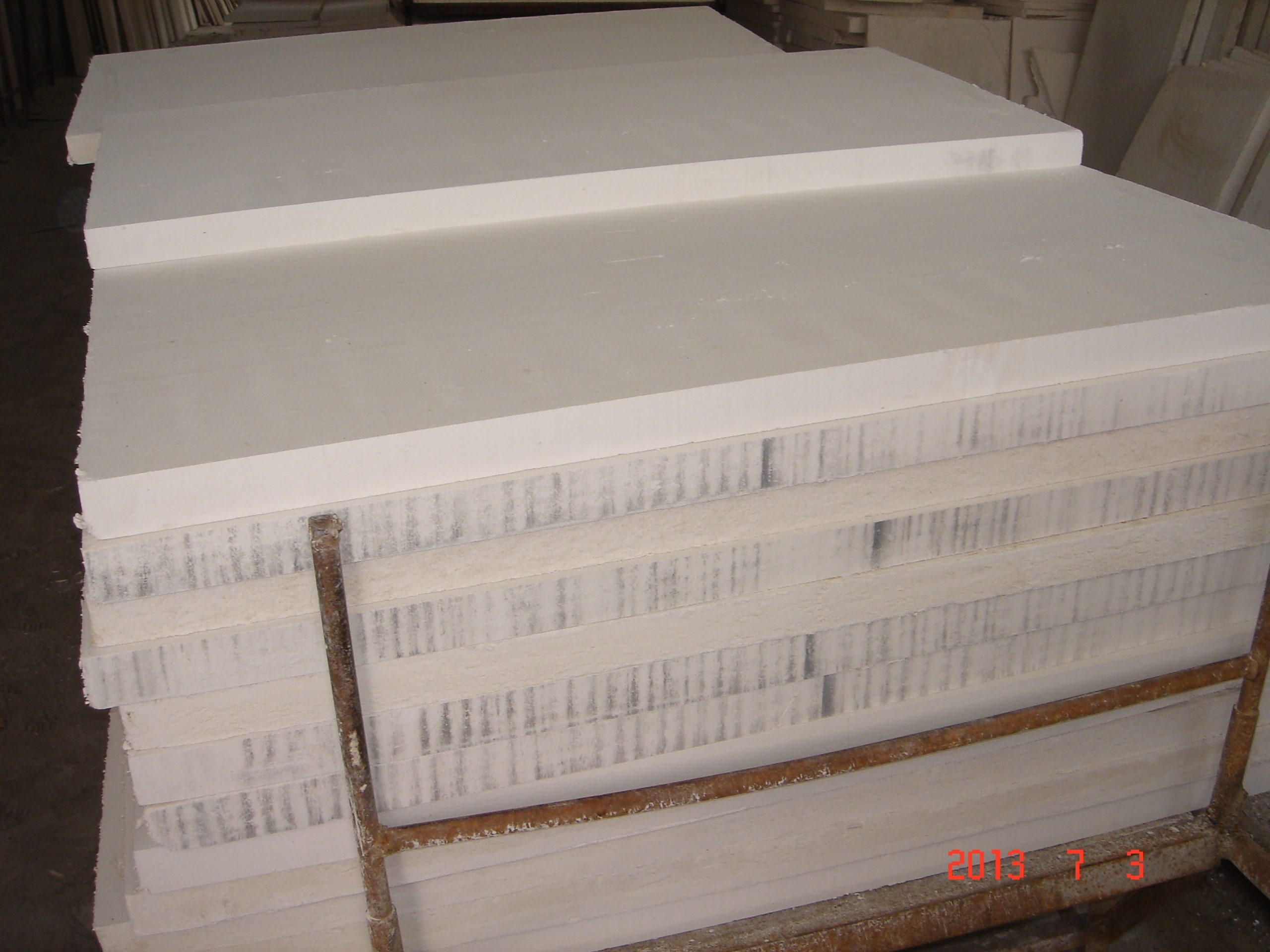

Calsium Silicate Fire-Proof Board has range density between 280-450kgs/m3. It is developed to provide outstanding service in demanding fire-proof application such as industrial chimney and flue part contact fire directly. It also can bear load and support different from refractory backup insulation. Uses include fire-rated enclosures around structural steel, tanks, equipment, and fire-proof doors.

With density range 750 – 900 kgs/m3, High Density calcium silicate insulation board is developed for the non-ferrous industry used for feeding, casting and molding of molten aluminum and other non-ferrous metals with its characteristic of non-stick aluminum.

It also can be used for clamping fixture of glass industry. Superior strength and good processability makes it the preferred material for precision CNC machined parts and complex components. There are two types, namely, glass fiber reinforced and carbon fiber reinforced.

Using silica fume (microsilica), quartz and lime as raw material, synthesized through dynamic hydrothermal process, reinforced with glass fibre and paper fibre and formed by press. Amorphous silica fill up interspace between xonotlite crystal, it increases fire-resistance temperature, mainly for back-up insulation of all refractory constructions.

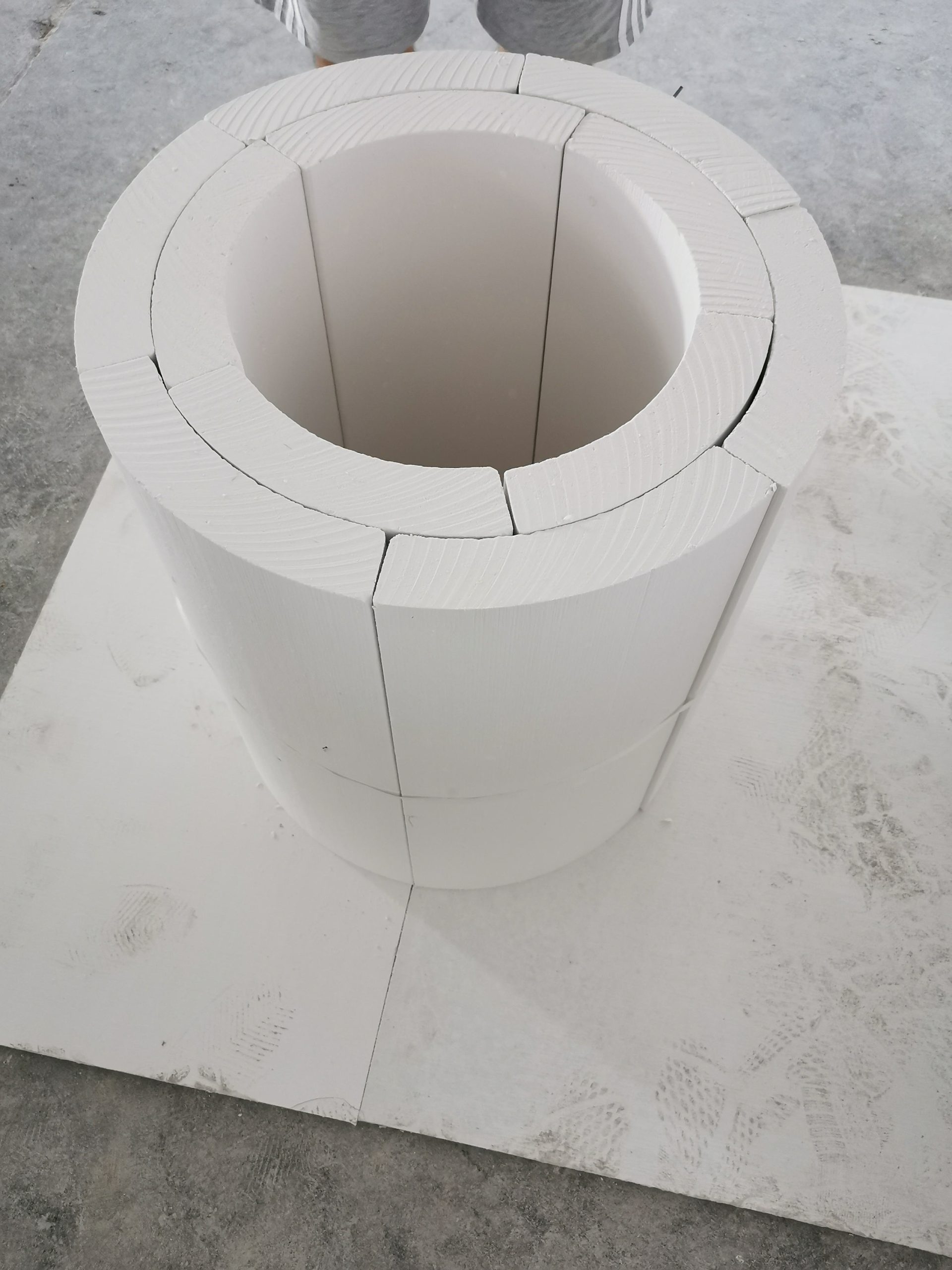

Calcium Silicate Pipe Cover 650 is produced by tobermorite and reinforced with paper fibre without asbestos. it has the temperature limit 650 oC. Calcium Silicate Pipe Cover 650 has characteristics such as low thermal conductivity, high rigidity and convenient construction, can be widely used for insulation in industrial furnaces and thermal pipelines.

Auxiliary Product – Calsium Silicate

High Temperature Adhesive – Calsium Silicate

Blended with water glass to form a mortar for the tight connection between insulationg board with board,also can be used for insulating board and other underdrop with consumption about 3.0kgs/m2.

Waterproof Agent – Calsium Silicate

When our insulating board is used with casting material and other monolithic refractories, waterproof agent is painted on the interface with consumption 3.0kgs/m2

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.