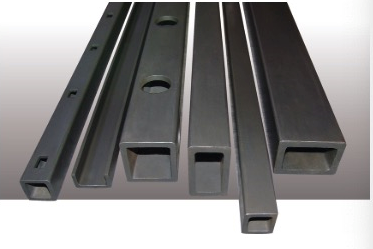

Typical applications for these products are support elements and posts for kiln car super structures, beams for two-channel kilns, joining systems for roof insulation as well as complete transport carriages

The appropriate beam cross-sections are designed according to individual specific loading conditions. The excellent performance of SISIC beams and profiles and their high degree of reliability in service have placed them in an important market position worldwide for sanitary ware and other applications such as electrical porcelain which involve super structures carrying heavy loads.

Advantages:

- High Modulus of rupture

- High thermal shock resistance

- Excellent oxidation and corrosion resistance

- Excellent long term creep-resistance

- Low mass

- High degree of reliability and economy in service

- High surface quality

Various forming processes are available depending on the different shape required by extrusion or slip casing. Both production methods are able to meet tight dimensional tolerances.

|

Cross-section |

Thickness (mm) |

Length (mm) |

Concentrated force/kg |

Distributed force/kg |

|

|

80 |

80 |

9 |

1000 |

979 |

1958 |

|

80 |

60 |

8.5 |

1000 |

746 |

1492 |

|

60 |

60 |

7 |

1000 |

423 |

846 |

|

60 |

50 |

6 |

1000 |

329 |

658 |

|

60 |

40 |

6 |

1000 |

276 |

552 |

|

50 |

40 |

6 |

1000 |

207 |

414 |

|

50 |

30 |

6 |

1000 |

165 |

330 |

|

40 |

40 |

6 |

1000 |

145 |

290 |

|

40 |

30 |

6 |

1000 |

114 |

228 |

|

40 |

20 |

6 |

1000 |

83 |

166 |

|

35 |

35 |

6 |

1000 |

105 |

210 |

|

30 |

30 |

6 |

1000 |

70 |

140 |

|

30 |

20 |

6 |

1000 |

50 |

100 |

|

20 |

20 |

6 |

1000 |

25 |

50 |

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.