Brown Aluminium oxide has high density and sharp, angular structure make it one of the fastest cutting abrasives available. It has long-lasting blasting abrasive that can be recycled many times. It is the most widely used abrasive in blast finishing and surface preparation because of its cost, longevity and hardness, harder than other commonly used –blasting materials.

It is an extremely durable and tough alumina with low metallic iron content and is ideal for applications where fast cutting and consistent quality is required.

Brown Aluminium Oxide is one of the most economical processing medias for many dry and wet process applications where anything from a coarse profile to a micro finish is required.

Applications :

Grinding, Polishing, Blasting, Refractory, Cleaning, Removing Corrosion, Roughening, Etching dan Decorating

General chemical composition :

| Al2O3 | 95.5 % |

| TiO2 | 2.7 % |

| SiO2 (not free) | 0.67 % |

| Fe2O3 | 0.25 % |

| CaO | 0.60 % |

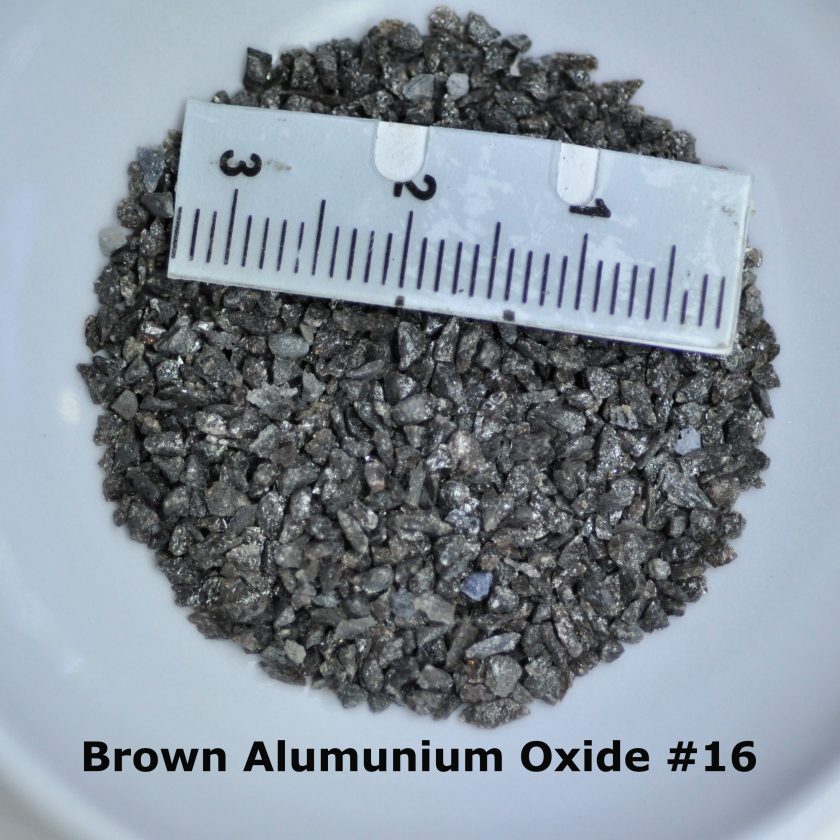

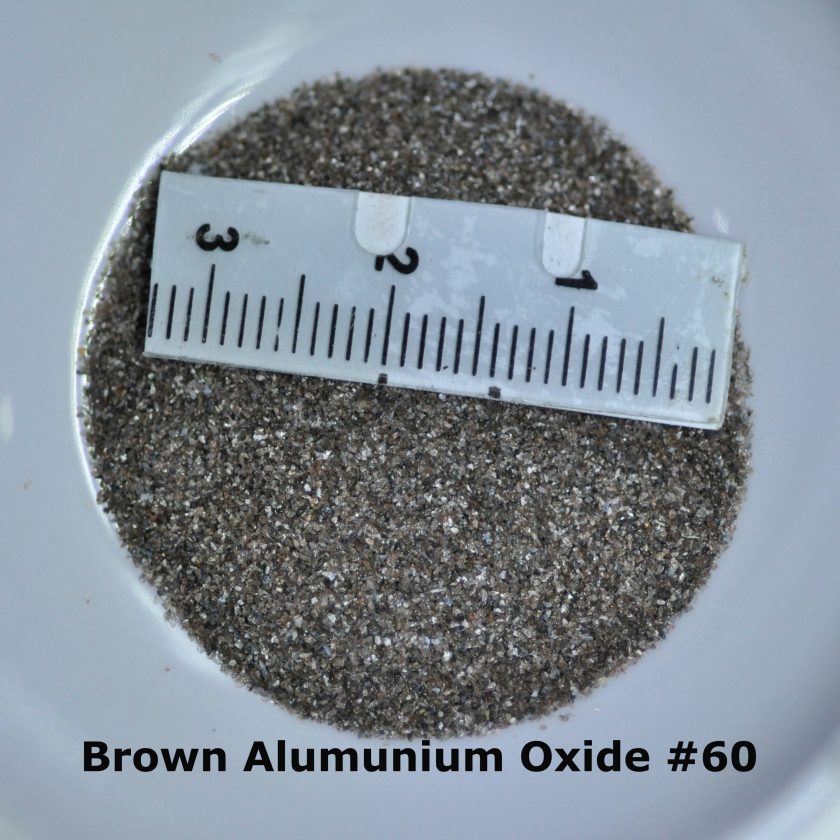

Size :

|

GRADE (Mesh) |

MICRONS |

mm |

GRADE (Mesh) |

MICRONS |

mm |

|

| 8 | 2360 | 0.560 | 80 | 180 | 0.125 | |

| 10 | 2000 | 0.500 | 90 | 166 | 0.100 | |

| 12 | 1700 | 0.450 | 100 | 150 | 0.090 | |

| 14 | 1400 | 0.400 | 120 | 125 | 0.071 | |

| 16 | 1180 | 0.400 | 150 | 100 | 0.063 | |

| 20 | 850 | 0.315 | 180 | 83 | 0.056 | |

| 24 | 740 | 0.280 | 220 | 68 | 0.050 | |

| 30 | 600 | 0.250 | 240 | 60 | 0.045 | |

| 36 | 480 | 0.225 | 320 | 45 | 0.038 | |

| 40 | 425 | 0.160 | 400 | 38 | 0.030 | |

| 46 | 326 | 0.160 | 500 | 28 | 0.025 | |

| 60 | 250 | 0.125 |

Grain Size comparison – Brown Alumunium Oxide :

| Brown Alumunium Oxide | White Alumunium Oxide | Silicon Carbide (Black) |

| Garnet | Glass Beads | Walnut Shell |

| Green Silicon Carbide | Monocrystal (Single) Fused Alumina Product |

For further information, you can contact our Sales Engineer, or you can contact us directly or here.