The cabin for wet-blasting can be made of glass fiber, reinforced plastic or stainless steel to avoid corrosion.

|

Model & Specification |

Cabin size (mm) & structure |

Max bearing capacity (KG) |

Storage box capacity |

Abrasive Pump |

Compressed air-supply |

|

Model: |

680 x 680 x 600 4mm-thick glass reinforced plastic |

20 KG |

25L water with 2-4 kg abrasive media |

Polyurethane |

2.1 – 5 bar |

|

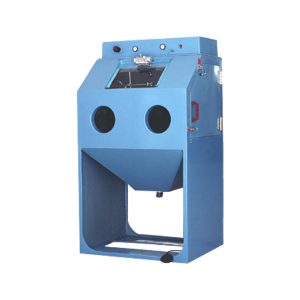

Wet type sandblasting cabinet |

|||||

|

Model: |

900 x 700 x 600 4mm-thick glass reinforced plastic |

20 KG |

30L water with 3-5 kg abrasive media |

Polyurethane |

3 – 7 bar |

|

Wet type sandblasting cabinet |

|||||

|

Model: |

900 x 900 x 600 4mm-thick glass reinforced plastic |

20 KG |

30L water with 3-5 kg abrasive media |

Polyurethane |

3 – 7 bar |

|

Wet type sandblasting cabinet |

Door and window: Tempered glass door and window with pneumatic water wiper

Abrasive Feeding Type: Wearable Polyurethane Abrasive Pump

Spray Gun: high efficiency tungsten steel nozzles

Air flow: 0.4 – 1.0 m3/minute connect with ½” piping system

Water supply: industrial tap water with ½” hose adaptor

Power supply: single phase 220V, 50Hz

For further information, you can contact our Sales Engineer, or you can contact us directly or here.