The newest generation of SOL-GEL castables for fast heating up conditions

Heating-Up problematic of standard dense monolithics :

─ Dehydration of the hydrat phases. Starting at 350°C.

─ Danger of spalling and explosions caused by steam forming if the heating up process can not be regulated properly.

Solution: Use of dense castables with a SOL-GEL setting system. VIBROLIT CASTING

Benefits of the VIBROLIT / NANO-G castables :

─ No hydrat phases, but a cross-linked Gel – Structure

─ High permeability of Gel – Structure. No chemical bounded H2O inside the castable

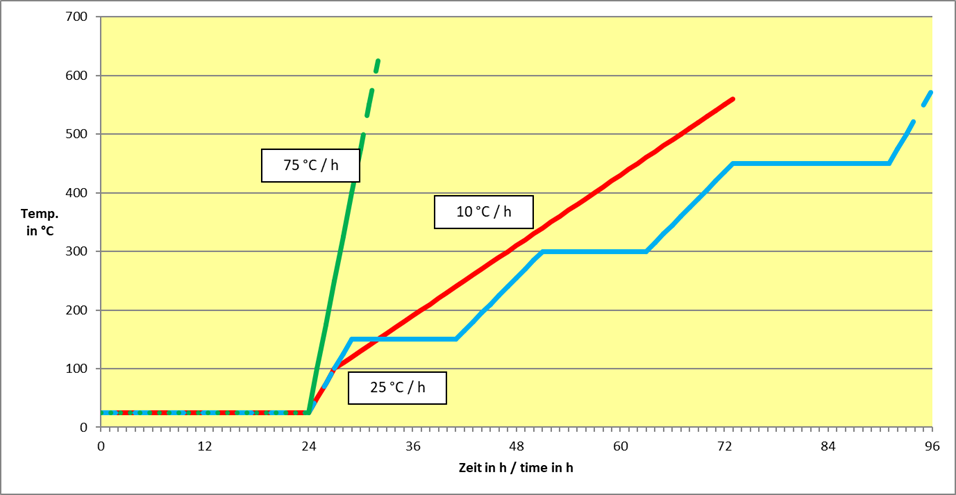

─ Possibility to heat up faster. Reduced danger of explosions and spalling

─ Better chemical resistance, less build up

─ Improved high temperature properties ( e.g AT, hot mechanical & errosion properties )

─ Longer storage lifetime ( min. 12 month )

|

Al2O3 (%) |

SiO2 (%) |

CaO (%) |

ZrO2/SiC (%) |

AT (°C) |

CCS 1500 °C (MPa) |

(t/m3) | |

| Vibrolit 64 A | 64 | 36 | < 0,4 | - | 1750 | 90 | 2,6 |

| Vibrolit 63 ZSI | 62 | 15 | < 0,4 | 13 / 7 | 1500 | > 120 | 2,9 |

| Vibrolit 78 KSI | 78 - 80 | 8 - 11 | < 0,2 | 7 | 1600 | 100 - 130 | 2,9 |

| NANO-G 63 ZSI | 58 – 63 | 14 – 18 | < 0,3 | 12 / 7 | 1450 | > 110 | 2,7 |

Application:

Cooler- front wall with Vibrolit (Cement Plant)

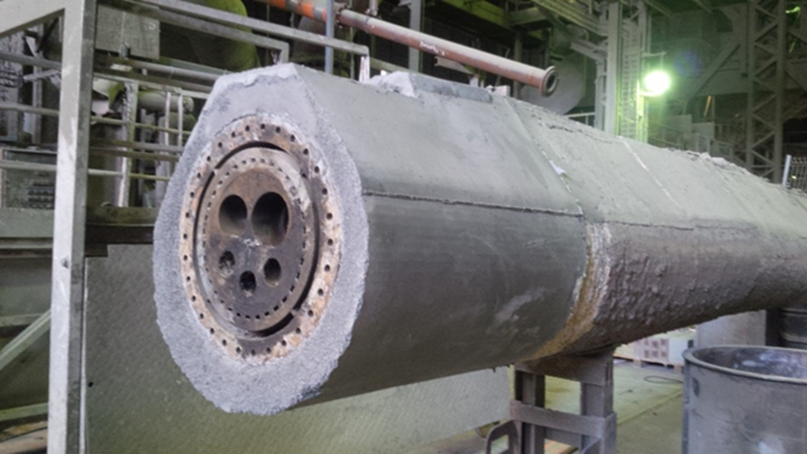

Burner-tip with Vibrolit

Nosering with Vibrolit

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.