Tumbling Stone Media (Alumina Polishing Stone Media)

Tumbling polishing stone media generally refers to various abrasives used in vibration (grinding) polishing machines, rolling (grinding) polishing machines, and also in centrifugal (grinding) polishing machines, eddy current (grinding) polishing machines and other (grinding) polishing machines.

The main shapes of ceramic grinding stones are: oblique triangle, oblique trigonal shape, oblique cylinder, and spherical shape.

Dressing Stick

The dressing stick can be used for dressing and sharpening , Grinding wheel dressing stick or stone is a special machine tool attachment for manual flat grinding, universal tool grinding, various surface grinders, curve grinders, dressing various straight-wheel and circular-arc cutting wheels.

Product Typical Size:

150 X 25 X 25mm SIC 24R

200 X 35 X 25mm SIC 24R

Any size even double size (combination stone ) is acceptable , as well as difference grit number and hardness, normally coarse grit are more popular for example grit 16, 20, 24, 30 and 36, hardness could be Q, R or S.

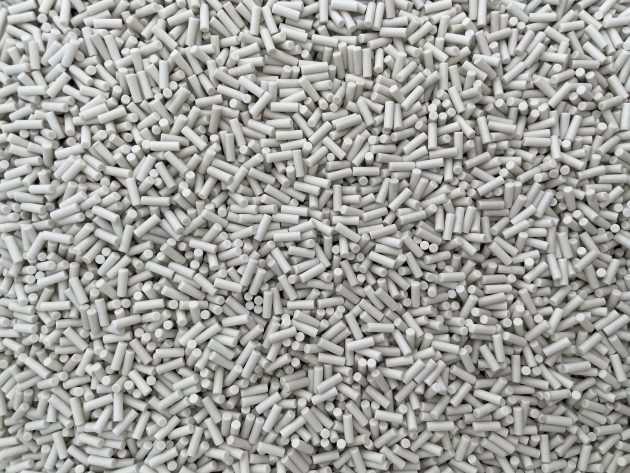

High Frenquency Polishing Stone Media

High frequency polishing stone media is a metal surface polishing material. Its surface is fine and wear-resistant, and its hardness is dozens of times higher than that of ordinary polishing stones. Commonly used for aluminum alloy, zinc alloy, copper alloy, stainless steel, white iron, titanium alloy, resin (plastic) and other materials surface polishing, light cutting, fine polishing, vibration, surface treatment before chemical treatment, fine grinding before plating.

Product Specification:

Cylindrical 1.3 × 3, 1.5 × 5, 2 × 8, 2.5 × 8, 3 × 10, 3.5 × 10, 4 × 14, 4.5 × 14, 5 × 16, 7 × 23.

No matter it is rough grinding or fine grinding, burrs removal or finishing, if you want to achieve the effect, It is necessary to use the abrasive liquid and brightener together, because in the vibration grinding process, whether the surface of the part is bright, whether it can meet the requirements, the abrasive and brightener play a decisive role!

Product Application:

Vibration-type grinding and polishing machines, barrel-type grinding and polishing machines, centrifugal polishing machines, and eddy current finishing machines.

Silicon Nitride Balls

Silicon nitride ball is a kind of precision ceramic sintered at high temperature in a non-oxidizing atmosphere. It has high strength, high wear resistance, high temperature resistance, corrosion resistance, acid and alkali resistance. It can be used in sea water for a long time. When at 800℃, the strength and hardness are almost unchanged, and the density is 3.20g/cm3 which almost 1/3 of the weight of the bearing steel. Moreover, the centrifugal force is small when rotating, so the high-speed operation can be realized. Silicon nitride balls also have self-lubricity, therefore it can be used for non-lubricated medium and high-polluting environment. In addition, they can be used as optional balls for the ceramic bearing and the mixed ceramic bearing.

Product Specification:

| Items |

Unit |

Silicon Nitride/Si3N4 |

| Rockwell Hardness | HRA | ≥75 |

| Volume Density | g/cm3 | 3.25 |

| Electric Volume Resistivity | Ω.cm | 1014 |

| Breaking Tenacity | Mpa m1/2 | 6~9 |

| Elasticity Modulus | Gpa | 300~320 |

| Thermal Expansivity | m/K *10-6/℃ | 3.1~3.3 |

| Thermal Conductivity | w/(m.k) | 15~20 |

| Weibull Modulus | m | 12~15 |

Product Application:

- Silicon nitride balls can be applied for various bearings with ultimate performance requirements, such as high speed or ultra-high speed bearings, high precision bearings, vacuum bearings, high or low temperature bearings, non-magnetic bearings, high precision ball screws.

- Silicon nitride can be used as valve balls, measuring balls using in chemical pump, high temperature pump and metering pump.

- Silicon nitride also can be used in sliding and measuring situation with various special requirements, such as high temperature slide rail and corrosion resistant slide rail.

- Silicon nitride ball is generally assembled into mixed bearings, which can be used in high-tech industries such as aviation, national defense, etc, as well as in chemical industry, metallurgy, medical treatment, food, oil field, electronics and other industries.

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.