Zirconia inserts are mainly used in continuous casting of steel billet. Zirconia inserts are made of magnesia stabilized and it has the chatarteristics of high density, excellent resistance.

Tundish metering nozzles consist of upper nozzle (stationary nozzle) and lower noozle (exchangeable nozzle).

Upper Nozzle is located within tundish lining and transfer the molten steel to controlling exchangeable nozzle, which determine the steel flow. Upper nozzle incorporates with a ultra high density zirconia insert. The zirconia insert provides excellent erosion resistance and extended casting sequence times.

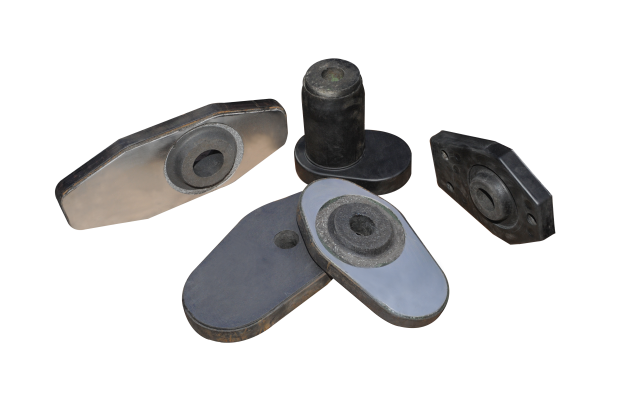

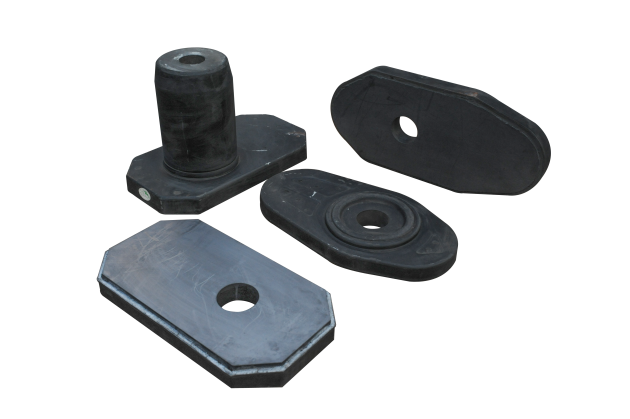

Lower nozzle (exchangeable) is located within assembly that is fixed to the bottom of tundish. The design of lower nozzle can vary according to the system manufacturer. Zirconia insert can be supplied for in-site assembly into metallic holding blocks where cementing, grinding, size banding and on site drying are required prior to use.

It was manufactured by cast process of fine grain alumina method and press process.

Upper nozzle and lower nozzle are suitable for several nozzle changer systems such as Concast (CNM), Danieli (FNC), Interstop (MNC), Krosaki (OTNC) and Vesuvius (CNY/SYS120).

High density zirconia sliding gate insert are used within sliding gate application. Zirconia Sliding Gate Plate Inserts can increase the life time of sliding gate plate. When the plate become worn and the worn material can be removed and a high density Zirconia Plate insert can be cemented in its place.

Atomising nozzle is used for powder metallurgy application. In the atomization process, nozzle control the flow of molten metal from the crucible.

Slide Gate Plate adopt tabular alumina, carbon and zirconia as raw materials. Slide Gate Plate has the properties of high strength, good erosion resistance, thermal shock resistance.

Inner Nozzle (Upper Nozzle) is made of tabular alumina, white fused alumina, sintered spinel, flake graphite and anti oxidant.

Collector Nozzle is made of tabular alumina, white fused alumina, sintered spinel, flake graphite and anti oxidant.

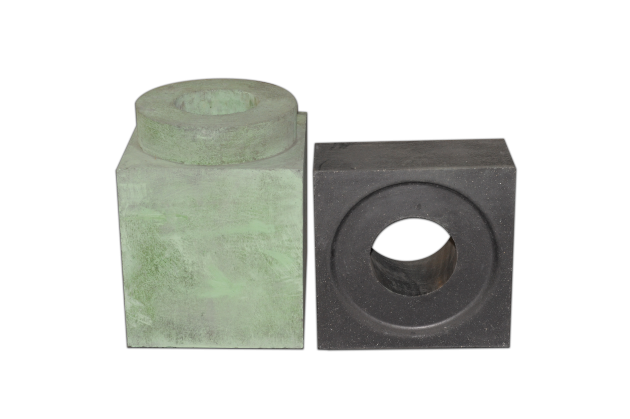

Well Block & Porous Plugs are used tabular alumina, green chromium oxide and magnesium aluminate spinel as raw materials with alumina cement as binder. It has good structural stability, high air permeability, strong corrosion resistant and long service life time.

Monocrystal (Single) Fused Alumina Product

Monocrystal (Single) Fused Alumina Product is produced from high purity Bayer Alumina.