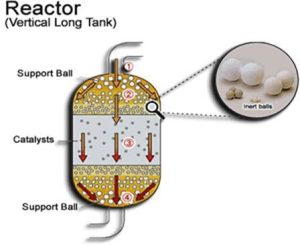

High Purity Alumina balls, also known as inert balls or catalyst support media are very important component in the catalytic process in the refinery, gas processing and petrochemical industry. It is commonly used to support catalyst and adsorbents products in the vessel or reactor. Its main function is to act as packing material and at the same time to support the catalyst bed in order to prevent breakthrough or loss of catalyst or adsorbent materials downstream of the reactor vessels due to the high pressure and temperature inside the reactor vessels during the operation.

Ceramic balls come in different sizes, which include 1”, 3/4”, 1/2”, 1/4” and 1/8”. These sizes are arranged layer by layer at the top and bottom of the vessel or reactor.

Typical application includes:

- Ammonia Production

- Methanol and hydrogen production (primarily reforming)

- Alkylation process using hydrogen fluoride at high temperature

- Naphtha reforming

- Isomerization

- Desiccant dryer

- Hydrocracker

- Petrochemical reaction

Chemical Composition and Physical Properties

| Products Specification | TP90® | TP95® | TP99N® | TP99D® | TP99.5® |

| Al2O3(%) | ≥90 | ≥95 | ≥99 | ≥99 | ≥99.5 |

| SiO2(%) | ≤6 | ≤2 | ≤0.2 | ≤0.2 | ≤0.15 |

| Fe2O3(%) | ≤0.3 | ≤0.15 | ≤0.12 | ≤0.12 | ≤0.1 |

| Compressive Strength N/¢13 | ≥2000 | ≥2000 | ≥5000 | ≥10000 | ≥15000 |

| Water Absorption(%) | ≤3 | ≤3 | 2-4 | <1 | <0.5% |

| Bulk Density (g/cm3) | ≥2.8 | ≥3.1 | 3.2-3.5 | >3.4 | 3.2-3.8 |

| Packing Densiti (g/cm3) | ≥1.7 | ≥1.9 | 1.9-2.0 | 2.1-2.2 | >2.2 |

| Crushing Strength | Excellent | Excellent | Excellent | Excellent | Excellent |

| Color | White | White | White | White | White |

Specification of Inert Alumina Ceramic Ball ((TP20® -TP70®)

| Products | TP20® | TP30® | TP40® | TP70® | |

| AL2O3% | 20-30 | 30-45 | 45-70 | 70-90 | |

| Water Absorption% | ≤3 | ≤3 | ≤3 | ≤3 | |

| Acid Resistance% | ≥98 | ≥98 | ≥98 | ≥98 | |

| Alkali Resistance% | ≥80 | ≥82 | ≥85 | ≥90 | |

| Thermal Shock

Resistance (from 800℃ - 20℃) |

No broken for

more than 3 times |

No broken for

more than 3 times |

No broken for

more than 3 times |

No broken for

more than 3 times |

|

|

Compressive Strength KN/pc |

Φ3 | ≥0.12 | ≥0.14 | ≥0.15 | ≥0.16 |

| Φ6 | ≥0.40 | ≥0.42 | ≥0.44 | ≥0.48 | |

| Φ8 | ≥0.48 | ≥0.52 | ≥0.60 | ≥0.62 | |

| Φ10 | ≥0.60 | ≥0.70 | ≥0.80 | ≥0.90 | |

| Φ12 | ≥1.00 | ≥1.10 | ≥1.30 | ≥1.50 | |

| Φ16 | ≥1.50 | ≥1.60 | ≥1.80 | ≥2.30 | |

| Φ20 | ≥1.80 | ≥2.00 | ≥2.30 | ≥2.80 | |

| Φ25 | ≥2.50 | ≥2.80 | ≥3.20 | ≥3.60 | |

| Φ30 | ≥3.00 | ≥3.20 | ≥3.50 | ≥4.00 | |

| Φ50 | ≥6.00 | ≥6.50 | ≥7.00 | ≥8.50 | |

| Packing Density (kg/m3) | 1.3~1.4 | 1.4~1.5 | 1.5~1.6 | 1.6~1.8 | |

Application Alumina Wear Resistant Ceramic Wear

For further information, you can contact our Sales Engineer, or you can contact us directly or here.