In water jetting applications, a focusing tube or nozzle’s highly wear resistance and consistently long service life means a reduction in the number of nozzles purchased over time and results in an optimum jet pattern and increased velocity thus significantly fastening average cutting speeds and reducing system downtime for consumable replacement and system calibration. Meanwhile, longer service life means greater dimensional accuracy and slow wear on the bore in other words, which contributes to cutting accuracy. Our Water Jet Nozzle made from XTC Pro™ series are your right choices towards cost- and quality-optimal cutting.

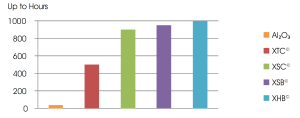

XTC Pro™ Composite Carbide is a unique tungsten carbide, which is manufactured without need to add such softer metal binders as nickel and cobalt widely applied in sintering tungsten carbide through traditional techniques. Under the innovative recipe of XTC Pro™, the carbide material could be quickly formed and thus consolidated at a relatively low sintering temperature, minimizing the natural tendency of raw material particles to grow in size when exposed to high heat for a long time. The material system is based on a nano-level low-binder ultra-fine tungsten powder. The nozzles which can ensure high cutting speed under a 600MPa water pressure for up to 160 hours are widely used in cutting all kinds of materials.

| P/N | OD (Inch) | ID (Inch) | L (Inch) |

| WJN -001 | 0.281 | 0.020 | 2 |

|

WJN -002 |

0.281 | 0.030 |

2 |

|

WJN -003 |

0.281 | 0.040 |

2 |

|

WJN -004 |

0.281 | 0.015 |

2.5 |

|

WJN -005 |

0.281 | 0.030 |

3 |

|

WJN -006 |

0.281 | 0.035 |

3 |

|

WJN -007 |

0.281 | 0.040 |

3 |

|

WJN -008 |

0.281 | 0.045 |

3 |

|

WJN -009 |

0.281 | 0.281 |

3 |

|

WJN -010 |

0.281 | 0.030 |

4 |

|

WJN -011 |

0.281 | 0.035 |

4 |

|

WJN -012 |

0.281 | 0.040 |

4 |

|

WJN -013 |

0.281 | 0.045 |

4 |

|

WJN -014 |

0.281 | 0.050 |

4 |

|

WJN -015 |

0.281 | 0.070 |

4 |

| WJN -016 | 0.281 | 0.060 | 6 |

We also supply Garnet for the waterjet process. Please see the product.

For further information, you can contact our Sales Engineer, or you can contact us directly or here.