For Abrasive is a naturally occurring mineral that has been used for a variety of purposes in the grinding industry.

Pyrite is a mineral with a metallic luster and a pale brass-yellow color. It has a cubic crystal system and a specific gravity of 4.95. It is insoluble in water and has a Mohs hardness of 6-6.5. It has high thermal conductivity and electrical conductivity and is a good thermal conductor. Pyrite is a sulfide mineral that is found in many sedimentary, metamorphic and hydrothermal environments. The mineral is composed of iron and sulfur and can be formed as crystals, masses, radiating aggregates, or stalactites.

Pink fused alumina is made from metallurgical grade chromium green and industrial alumina by chemical reaction at the high temperature above 2000℃. The product has good stability in high temperature, scouring resistance, erosion resistance and wear resistance. The color of pink fused alumina is pink, and can be used for manufacturing abrasives. Abrasive tools made of it have good durability and can achieve high finish when grinding.

Product Application:

- It is an ideal sandblasting, and applicable to hardware, glass, zinc alloy, aluminum alloy, stainless steel, high carbon steel, high-speed steel and other sandblasting.

- It can improve the smoothness of silicon wafer, optical lens, precision instrument, polished glass shell, glassware, ceramic stone, leather, plastic and metal parts.

- It is suitable for precision grinding of measuring tools, machine tool spindles, instrument parts, thread workpieces, etc.

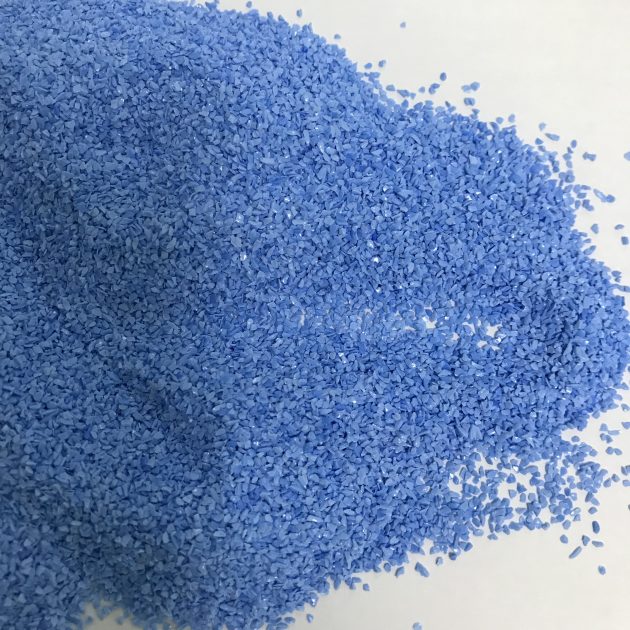

Blue ceramic abrasive grains are a kind of sintered abrasive grains made by sol-gel method with with special alumina as main raw material and various modified components as auxiliary materials. The grain size of it is very small, only 100-300 um.

Product Application:

Blue ceramic abrasive grains can be used for making bonded abrasives and coated abrasives. It has a wide range of applications, ranging from heavy duty grinding to fine grinding of a variety of materials, including gear grinding, bearing grinding, crankshaft grinding, roll grinding and others.

Zirconia fused alumina is made of alumina and zirconia as raw materials in an electric arc furnace at a high temperature of 2000 ℃ or higher.

ZA25% is an electroed zirconia grainnby fusing alumina and zirconia at about 2000 ℃ temperature in an electric arc furnace. Following a unique process of quenching, crushing, and resizing.

ZA40% produced by melting alumina and Zirconia at about 2000 ℃ temperature in an electric arc furnace followed by cooling of the motion product. The very fine and homogenous microstructure of this materials provides high toughness but also excellent self sharpening properties.

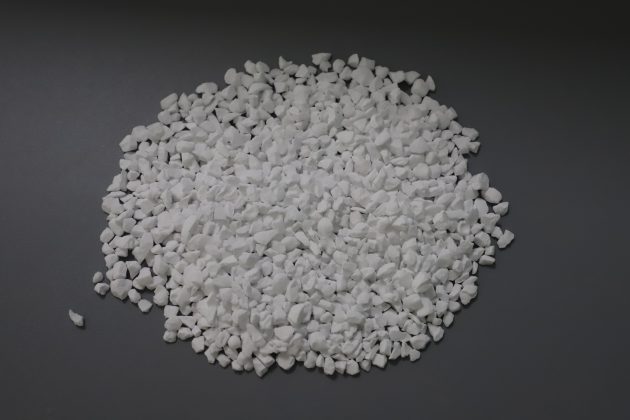

Tabular alumina is made of aluminum oxide as raw material. After being mixed, ground and shaped and sintered, it is completely recrystallized into α- Al2O3 under the condition of ultra-high temperature but slightly below the melting point.

The crystals of tabular alumina are staggered in a flat pattern which increases the mechanical strength of the particles. The closed pores distributed evenly In crystals and between crystals, high bulk density, low apparent porosity and water absorption, which reduces the amount of liquid used in the remanufactured products. Moreover, the alkaline oxide content in the product was significantly reduced because of the unique technology of sodium removal. The tabular alumina has the superior physical properties, such as high refractoriness, good thermal shock stability, low thermal shrinkage rate and good strength of thermal load. At the same time, the high purity avoids the pollution to the system due to the impurities. Tabular alumina is an ideal material for making advanced refractory, ceramic and insulating materials.

Semi-Friable Aluminum Oxide Tumbling Stone Media

Semi-friable Aluminum oxide is produced by aluminum oxide, then melt in an electric furnance at high temperature of more than 2000℃. Because it not only has reasonable hardness, but also has reasonable brittleness which is between white fused aluminum oxide and brown fused aluminum oxide, it is named Semi-friable Aluminum oxide.

Product Application:

The process of heat-sensitive steel, ordinary steel, various stainless steel, special alloy steel, non-metallic materials like wood, plastic, leather and paint.

Chrome oxide is an inorganic substance with the chemical formula Cr2O3. It is a small hexagonal crystal from light green to dark green. It turns brown when hot, and still turns green when cold. The crystals are extremely hard and stable, and there is no change even if hydrogen is injected under red heat. It is soluble in heated potassium bromate solution, slightly soluble in acids and alkalis, and almost insoluble in water, ethanol and acetone. There is also irritation molecular weight is 151.99, in hexagonal system, light green or dark green powder.

Chrome oxide is used to make abrasive materials, widely used in stainless steel, diamond, precision machine, etc. for polishing and abrasive. SA-2 (one of COG material) is used in stainless steel for no scratch polishing surface of large area, with high-precision. And it can be used for green cutting and grinding disc.