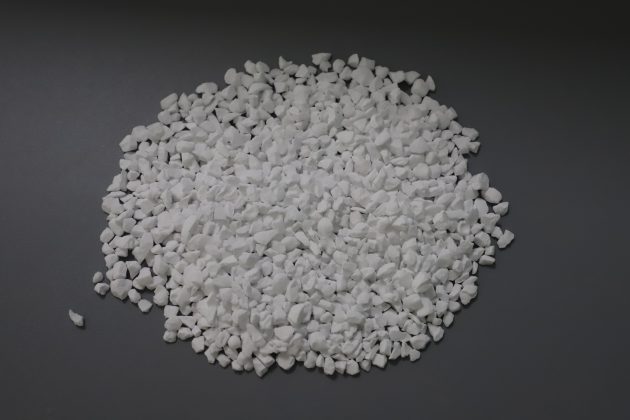

Tabular alumina is made of aluminum oxide as raw material. After being mixed, ground and shaped and sintered, it is completely recrystallized into α- Al2O3 under the condition of ultra-high temperature but slightly below the melting point.

The crystals of tabular alumina are staggered in a flat pattern which increases the mechanical strength of the particles. The closed pores distributed evenly In crystals and between crystals, high bulk density, low apparent porosity and water absorption, which reduces the amount of liquid used in the remanufactured products. Moreover, the alkaline oxide content in the product was significantly reduced because of the unique technology of sodium removal. The tabular alumina has the superior physical properties, such as high refractoriness, good thermal shock stability, low thermal shrinkage rate and good strength of thermal load. At the same time, the high purity avoids the pollution to the system due to the impurities. Tabular alumina is an ideal material for making advanced refractory, ceramic and insulating materials.

Product Specification:

Chemical Composition

| AL2O3 % | Fe2O3 | Na2O | SiO2 |

| ≥99.2 | ≤0.2% | ≤0.2% | ≤0.4% |

Physical properties:

| Bulk density | Apparent porosity | Water absorption |

| 3.5ɡ/cm³ | ≤5% | ≤1.5% |

Product Application:

- Refractory materials, furnace charge, aggregate, casting materials, mouldable materials, die casting materials, sling refractories, coat-injecting materials, vibrating materials, refractory mud and so on.

- Wear resistance coating, refractory products, wear-resisting machinery.

- Deburring and surface treatment.

- Firebrick, refractory ceramics, etc.